- Home

- Steam Resources

- Steam Theory

- Waste Heat Recovery

Energy Efficiency

Waste Heat Recovery

What is Waste Heat Recovery?

”Waste heat recovery” is the process of “heat integration”, that is, reusing heat energy that would otherwise be disposed of or simply released into the atmosphere. By recovering waste heat, plants can reduce energy costs and CO2 emissions, while simultaneously increasing energy efficiency.

Typical Examples of Waste Heat Recovery

Several common consumer items recover waste heat. For example, consider turbocharged cars, which are provided by multiple car manufacturers.

In regular, non-turbocharged cars, the internal combustion gasoline engine expels hot gas through the car’s exhaust after its fuel is burned. That gas contains both heat and kinetic energy—a portion of which can be recovered. Turbocharged engines divert the hot gas to a turbine, which is used to spin an air compressor. The compressed air is routed to the engine’s combustion chamber with the vaporized gasoline, resulting in a more efficient ignition and greater power made with lower fuel consumption.

The energy benefits of industrial waste heat recovery can be similar, and some examples are examined in this article.

Economizer

Stack economizers, commonly used to heat water, are among the simplest type of waste heat recovery. Plant workers may be familiar with these common devices that recover waste heat. Boiler stack economizers use heat energy from the gas expelled in the heating process into the stack to heat boiler feed water and reduce the amount of energy required to make steam. According to the US Department of Energy, installation of a boiler feed water economizer can raise the thermal efficiency of a boiler and reduce fuel consumption by 5 - 10%.

Waste Heat Boiler (WHB)

Using a principle similar to economizers, waste heat boilers recover heat generated in furnaces or exothermic chemical reactions at industrial plants. These locations may contain significant energy that should not be wasted up a stack. Instead, this energy can be captured to generate low-to-medium pressure steam in a waste heat boiler (WHB). A WHB can also be used to remove the heat from a process fluid that needs to be cooled for either transport or storage, and generate steam from that heat. The steam generated in WHB may be used for heating applications, or to drive turbines that generate electricity, compress vapors, or pump liquids. WHB steam may contain significant wetness, so it is recommended that a high efficiency separator and steam trap combination is installed to ensure that the WHB delivers optimal quality steam to the recipient process.

Heat Recovery Steam Generator (HRSG)

Many highly efficient industrial plants with cogeneration or combined cycle systems use a gas-turbine (essentially a jet engine) to generate electricity then create steam from the waste heat using a heat recovery steam generator (HRSG). This section will explain how this process works and how an HRSG comes into action.

Consider the previous example of a turbocharged car engine, but instead change the motor to a jet engine. The gas-turbine/jet engine is fired using natural gas and its exhaust contains extremely hot vapor that would simply be expelled to atmosphere if some of the heat and kinetic energy were not captured. So, how can that waste heat be used as was done with the turbocharged auto? The expelled hot gas needs to drive another turbine, so the exhaust is passed through a HRSG, which creates superheated steam that drives a downstream steam-turbine. The turbine can either drive a generator (combined cycle system) or just use the steam in process applications (cogeneration or combined heat and power (CHP)). HRSGs can have either a single steam drum (as shown in the animation below) or multiple steam drums and pressures. There are also both unfired varieties with natural circulation (shown below) and varieties with duct firing, which is additional heating. Duct firing increases steam generation and quality, and has the ability to create superheated steam and even greater power at a turbine.

Absorption Chiller

Some energy efficient CHP systems may add refrigeration by incorporating absorption chillers that use steam created from waste heat.

The mechanism of absorption chillers can be broken down into the following stages:

- Diluted absorbent liquid (60% lithium bromide salt, 40% water) is preheated with condensate as it moves from the absorber to the generator.

- In the generator, the absorbent liquid is heated by steam, which causes some of the water contained within it to vaporize, making the liquid more concentrated.

- The concentrated absorbent liquid flows downward back to the absorber to capture more water in its continuous loop. At the same time, the water vapor moves to the condenser.

- In the condenser, cooling water causes the vapor to liquify and flow downward toward the evaporator, which has near vacuum pressure.

- Just prior to entering the evaporator, the condensed water flows through an orifice or expansion valve. This restriction limits flow, and the water again vaporizes to a cold mist at 4.5°C [40°F]. This is where refrigeration occurs. The low temperature vapor pulls heat out of the chilled water loop, lowering its temperature by about 5°C [9°F].

- The mist is heated when it absorbs heat from the chilled water loop, but the strong attraction of the concentrated salt solution pulls the water into the concentrated absorbent into the absorber, creating near vacuum pressure in the evaporator in the process.

- Evaporator: Actual refrigeration occurs here. Water passes through a valve, creating a low temperature mist. Sprayed over the chilled water loop, it absorbs heat and cools the refrigerant.

- Absorber: Concentrated absorbent attracts water mist from the evaporator, creating near vacuum pressure while diluting the absorbent.

- Generator: The 60/40% mixture absorbent is heated, evaporating the water, with the concentrated (regenerated) absorbent returning to the absorber.

- Condenser: The water vapor supplied from the generator is condensed by transference of heat to cooling water.

Steam Thermocompression

Thermocompression is another heat recovery approach that can utilize the energy in an otherwise wasted stream, such as low-pressure steam. This is the process of mixing high-pressure and low-pressure steam to create an intermediate pressure using steam compression equipment such as TLV’s SC System, which is shown below.

For more information, see:

Other Examples of Waste Heat Recovery in Steam Systems

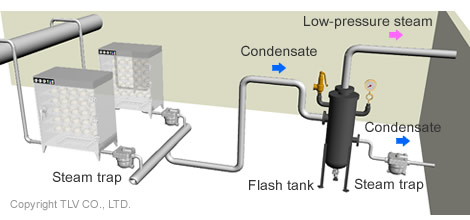

Separation and Reuse of Flash Steam

Wherever flash steam occurs, the possibility of its use as a low-pressure steam source should be considered.

Boiler Blowdown

The heat from boiler blowdown can be used in a vessel such as TLV’s SR series to preheat water.

For more information, see:

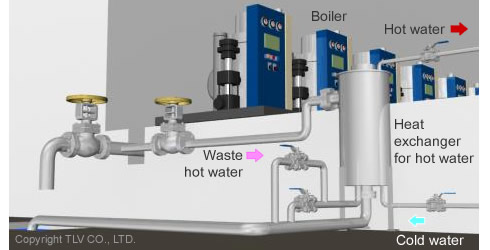

Steam-Fired Water Heating

Low-pressure steam can be used to make hot water for process or domestic use. If the supply of steam from a waste heat source is not continuous, the supplied steam can be kept constant by using a supplemental steam valve. TLV's steam-fired water heater, SteamAqua®, is a typical example. For optimized efficiency, the SteamAqua® series contains a preheat section that uses the condensate’s heat energy to preheat feed water.

Heat Recovery Opportunities

There are often many opportunities for heat recovery in steam systems, including some which may not be included in this article. Please contact your local TLV Technical Representative or Consulting · Engineering · Services (CES) team member for additional information on how to recover heat energy from your system.