- Home

- Products

Products

Fluid Control Equipment

Products used in the field for steam, air, and water piping.

Steam Traps

Automatic valve that discharges condensate (condensate) without leaking steam.

Steam Trap Stations

Compact, reliable steam trap stations for condensate drainage from steam mains, tracers and light processes.

Condensate Recovery

Condensate recovery pumps suitable for use in high-lift closed recovery applications and mechanical applications where the use of electric power is not possible

Waste Heat Recovery

Equipment to recover heat energy from flash steam and high-temperature waste water.

Pressure Reducing Valves

Pressure reducing valves for steam and air. A wide assortment of models is available, including pilot-operated models, direct-acting models and models with integral separators and steam traps.

Control Valves, Controllers

Multi-purpose control valves and high-precision control valves for steam.

Vortex Flowmeters

Vortex flowmeters and flow computers. Measure the flow rates of a variety of fluids, including steam, air, and water.

Cyclone Separators

Separators are used to remove entrained water from air or steam as it is transported.

Filters

Separator filter for use on steam and other gasses (non-toxic, non-flammable).

Sensors

Pressure transmitters and temperature sensors for steam applications.

Valves

A variety of valves for use on steam, air, water, etc.

Check Valves

Automatic valves for preventing backflow.

Air Vents

Includes both air vents for liquid and air vents for steam. These automatic valves for air removal make use of the same reliable technology utilized in our steam traps.

Vacuum Breakers

Float-type mechanical valve to protect against piping and equipment damage by preventing a vacuum from forming.

Air and Drain Traps

Automatic valves for removing condensate from air and non-flammable, non-toxic gas.

Manifolds

Manifolds suitable for use on steam supply branches and for convergence condensate from trace lines, etc.

Strainers, Sight Glasses and Other

Strainers, sight glasses, and non-freeze valves used in the steam trap periphery.

System Products

Optimised yet simple solutions to problems in the fields of process steam control and condensate recovery technology.

Vacuum Steam Heating Systems

An innovative system that utilizes vacuum steam for heating and cooling under 100 °C.

Steam-Fired Instantaneous Water Heater

Compact, high capacity instantaneous water heater with simple operation.

Condensate Recovery Pumps

Condensate recovery pumps with motorized condensate transport.

Steam Compressor

Steam compressor that recovers low pressure steam at higher pressure for reuse.

Steam Desuperheating Systems

Space-saving, high-precision desuperheating system

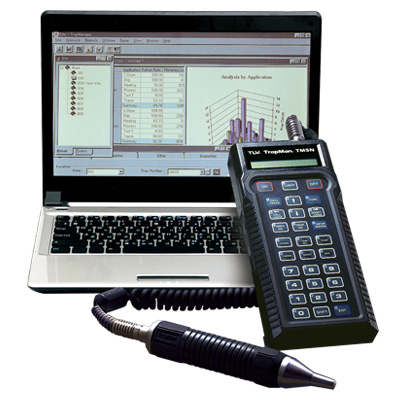

Maintenance Instruments

Energy conservation survey tools for steam trap management.