Fluid Control Equipment

Cyclone Separators for Air (with Built-in Trap)

DC3A/DC5A

Why a Separator is Necessary

High velocity condensate flows through the drip leg

Drip legs are designed to remove a considerable portion of the condensate flowing through piping – that which has fallen out of the air flow, but cannot remove the water droplets entrained within the flow itself.

Cut-view of Condensate Discharge Through Drip Leg

Water droplets entrained in air will be carried over and pass by the drip leg because of the speed at which the air flows through piping.

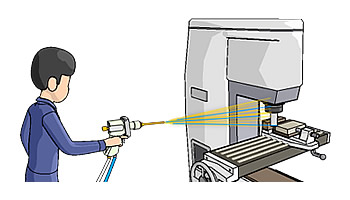

Examples of problems caused by water droplets in piping

Air Blowers

Water droplets in a compressed air line may cause product defects when the droplets come in contact with the product.

Pneumatic Cylinders

Water droplets in air cylinders can affect the movement of pistons or cause damage to other parts, which may lead to the breakdown of equipment.

Reliable separation and elimination of condensate and water droplets

DC Series: Up to 98% Separation Efficiency

Condensate entrained in air is mechanically removed using a cyclone separator for air.

How condensate and water droplets can be mechanically separated

| Label | Description |

|---|---|

| A | High-performance cyclone separator |

| B | Free Float® Air trap |

Centrifugal force is used to separate entrained water droplets from air, by taking advantage of the difference in the specific gravities of liquid and gas to separate the two. In this case, air is channeled into a spiral flow, causing the heavier condensate droplets to be flung out of the flow and onto the inner wall of the separator. Gravity then pulls the condensate down to the bottom of the separator where a built-in free float air trap is installed to discharge it.

High-performance Super Cyclonic Effects separator (SCE)

The DC series separators use a cyclone separator to separate and remove water droplets from air with 98% efficiency (at a flow velocity of 30 m/s). High velocity centrifugal force and directional changes are key factors that enable such a high degree of separation.

Free Float® Air Trap

The Free Float® enables continuous discharge of condensate while still keeping an air-tight seal. This rapid discharge design with no back-up is essential to prevent condensate from being re-entrained into the air flow.

Effect of flow rate on separation efficiency