- Home

- Products

- Waste Heat Recovery

- High-Temperature Waste Water Heat Exchanger

Fluid Control Equipment

High-Temperature Waste Water Heat Exchanger

SR-B Series

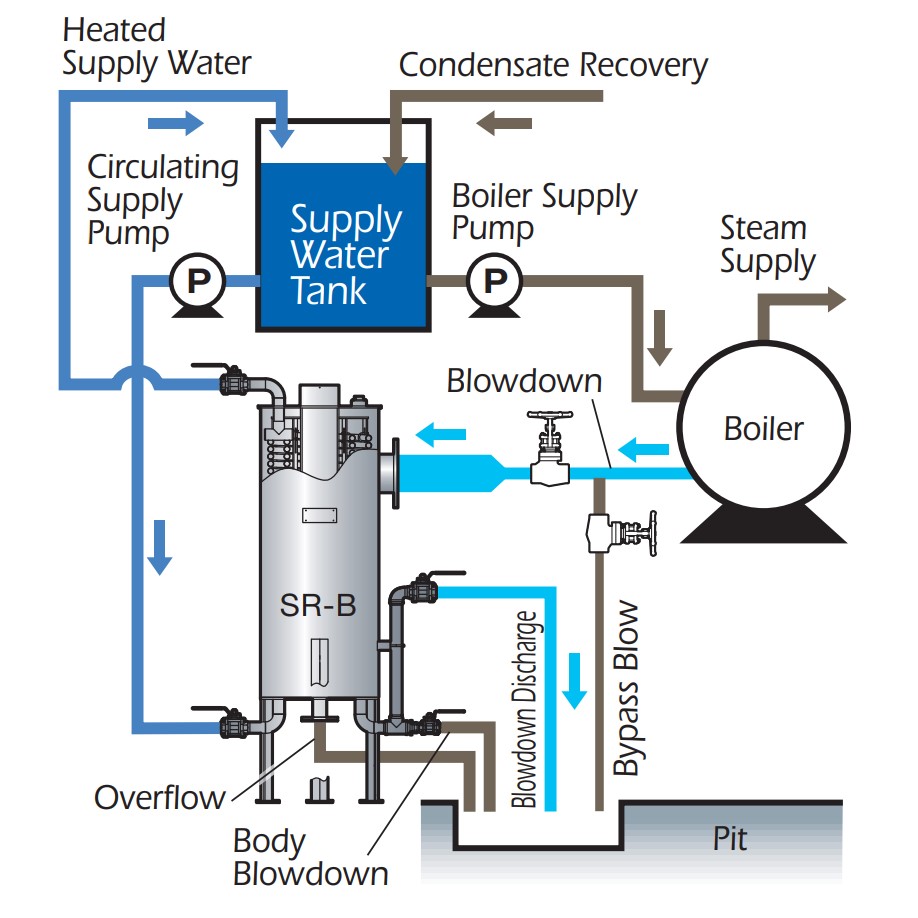

Deliver energy savings by heating supply water with high-temperature waste water!

High-performance atmospheric indirect heat exchanger for recovering heat energy from high temperature waste water (100°C or more).

Flash Steam and Waste Water Heat Exchangers Pamphlet (806 KB)

Benefits and Features

Highly Efficient Heat Exchange

Heat exchange efficiency comparable to closed type heat exchangers.

Value for Money

Requires no electric power, providing very high economic efficiency.

Super Safe

Open to atmosphere system adds very little back pressure to steam-using equipment.

Improves work environment by eliminating steam clouds.

Application Areas

Recovers waste heat generated from steam-using equipment.

Utilises the energy from 100°C and higher condensate unsuitable for recovery to heat water for reuse.

Product Details

| Model | Photo | Body/Heat Transfer Coil Material | PMO (MPaG) | TMO (°C) | Maximum High Temperature Water Flow Rate (kg/h) | Specifications | Manual | |

|---|---|---|---|---|---|---|---|---|

| Body (shell side) | Coil (tube side): 1.0 | |||||||

| SR-B1.5 |  | Stainless Steel SUS304 | 0(*1) | 1.0 | 100(*1) | 1000(*2) | Specifications | Manual |

| SR-B4 | Stainless Steel SUS304 | 0(*1) | 1.0 | 100(*1) | 2400(*2) | |||

- *1: Even if the pressure and temperature of the high temperature water exceed the PMO/TMO before re-evaporation, the interior of the heat exchanger will be at nearly atmospheric pressure and 100 °C or less if within the maximum processing rate.

- *2: For heat exchange with high-temp. water at 160 °C and cold water at 20 °C.

- PMO = Maximum Operating Pressure

- TMO = Maximum Operating Temperature

The latest version of each product's instruction manual can be found on this page.