Fluid Control Equipment

Cyclone Separators for Steam (with Built-in Trap)

DC Series

Case Study: Incorporating separators into equipment for simple, compact configuration

Dry steam supply to superheated steam generator

| Equipment used |

|

|---|

Problem

Superheated steam generators are often newly introduced equipment, and it is difficult to generate space for installation because they are additional equipment for the site.

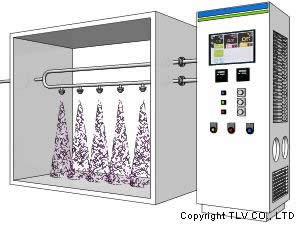

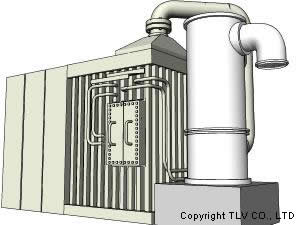

Superheated steam generator

Solutions

- The less water droplets of condensate mixed in the original steam supplied, the higher the efficiency, and the more compact the design can be. Therefore, a cyclone separator with high water droplet separation efficiency and a pressure reducing valve with a built-in separator trap were adopted, and the equipment was successfully made more compact.

- Significantly reduces installation space

- Separator prevents contamination

Key improvements

- A cyclone separator with high separation efficiency reliably removes water droplets, thereby minimizing the number of heating elements.

- A pressure reducing valve with a built-in separator trap significantly reduces installation space.

Supply of dry steam to deodorization equipment

| Equipment used |

|

|---|

Problem

When deodorizing with a steam ejector, the smaller the condensate droplets mixed in the supplied steam, the more stable the vacuum and the more reliable the deodorization.

For this reason, installation of a separator is effective, but in many cases, separators are not initially installed, and it is difficult to generate space for new installation.

Deodorization equipment

Deodorization equipment

Solutions

- Install a separator or a pressure reducing valve with a built-in separator/trap in the supply steam piping to remove water droplets in the steam.

- Adoption of a separator with a built-in trap eliminates the need for a new installation space.

- Adoption of pressure reducing valve with built-in separator significantly reduces installation space.

Key improvements

- Cyclone separator with high separation efficiency reliably removes water droplets

- DC3S has a built-in trap, eliminating the need for a new installation space

- Pressure reducing valve with built-in separator and trap further reduces installation space significantly.