- Home

- Steam Resources

- Steam Theory

- Steam Pressure Reduction

Basics of Steam

Steam Pressure Reduction

How to generate low-pressure steam

Steam for heating is typically generated at the boiler. The pressure of this generated steam is usually set to the highest pressure required within a facility.

However, the steam generated from the boiler might be unsuitable for use in certain applications due to the pressure rating of the equipment or the temperature required in the process. In such cases, the steam pressure is reduced ahead of the process, adjusting its temperature to the required level. This is the main reason for pressure reduction in the plant: to manage temperature.

Pressure reducing valves, or PRVs for short, are used to lower the pressure to an acceptable level for the steam application. This valve automatically adjusts to maintain the desired steam pressure, compensating for fluctuations in the steam flow. At its core, the mechanism involves constricting a part of the flow path to reduce pressure. This is the primary method for regulating steam pressure in heating applications.

Principles of pressure reduction

The constriction in the valve serves to limit the flow rate of the steam. By limiting the flow rate, it balances the steam usage and supply, adjusting the pressure as follows:

- Steam usage < steam supply ⇒ pressure rises

- Steam usage > steam supply ⇒ pressure drops

- Steam usage = supply ⇒ pressure remains stable

This concept is easier to understand if you imagine a scenario where a globe valve or needle valve is used for pressure adjustment. If you have a consistent load and stable steam flow, you can adjust the opening of these valves to a semi-fixed position, which will also effectively reduce the pressure.

However, as the amount of product to be heated fluctuates, so does the pressure. This means manual valve adjustment is needed to maintain the desired pressure. Once the load stabilizes, a quick adjustment can keep the pressure at the desired setting again.

How pressure reducing valves work

If you were able to adjust the valve continuously and react to changes in load you could maintain stable pressure. This is exactly what a PRV does automatically.

As the animation below shows, inside the PRV, a diaphragm (or similar mechanism) works in tandem with an adjustment spring to automatically regulate its opening ranging from fully open to fully closed, adapting to varying load conditions.

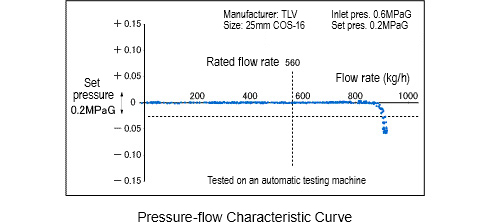

The "pressure-flow characteristic curve" used to evaluate the pressure stability of a PRV indicates how the secondary pressure is determined by the balance of demand and supply.

What happens to the primary pressure?

You might wonder: when the flow rate is restricted using a pressure reducing valve, what happens to the pressure on the primary side of the valve? Does it remain unchanged? If the boiler produces more steam than required, the steam pressure will inevitably rise.

To counteract this, modern boilers are equipped with a control system that responds to various measurements in the system. The control system allows the boiler to match the amount of steam produced to the demand, ensuring that the set steam pressure is maintained and thus flow rate restrictions by the pressure reducing valve (or valves) do not cause fluctuations in the pressure on the primary side.