- Home

- Products

- Pressure Reducing Valves

- Pressure Reducing Valves for Process Steam (with Built-in Separator & Trap)

- Applications

Fluid Control Equipment

Pressure Reducing Valves for Process Steam (with Built-in Separator & Trap)

COS Series

Case Study: Incorporating separators into equipment for simple, compact configuration

Dry steam supply to superheated steam generator

| Equipment used |

|

|---|

Problem

Superheated steam generators are often newly introduced equipment, and it is difficult to generate space for installation because they are additional equipment for the site.

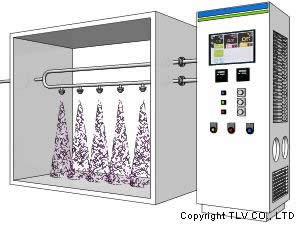

Superheated steam generator

Solutions

- The less water droplets of condensate mixed in the original steam supplied, the higher the efficiency, and the more compact the design can be. Therefore, a cyclone separator with high water droplet separation efficiency and a pressure reducing valve with a built-in separator trap were adopted, and the equipment was successfully made more compact.

- Significantly reduces installation space

- Separator prevents contamination

Key improvements

- A cyclone separator with high separation efficiency reliably removes water droplets, thereby minimizing the number of heating elements.

- A pressure reducing valve with a built-in separator trap significantly reduces installation space.

Supply of dry steam to deodorization equipment

| Equipment used |

|

|---|

Problem

When deodorizing with a steam ejector, the smaller the condensate droplets mixed in the supplied steam, the more stable the vacuum and the more reliable the deodorization.

For this reason, installation of a separator is effective, but in many cases, separators are not initially installed, and it is difficult to generate space for new installation.

Deodorization equipment

Deodorization equipment

Solutions

- Install a separator or a pressure reducing valve with a built-in separator/trap in the supply steam piping to remove water droplets in the steam.

- Adoption of a separator with a built-in trap eliminates the need for a new installation space.

- Adoption of pressure reducing valve with built-in separator significantly reduces installation space.

Key improvements

- Cyclone separator with high separation efficiency reliably removes water droplets

- DC3S has a built-in trap, eliminating the need for a new installation space

- Pressure reducing valve with built-in separator and trap further reduces installation space significantly.

Case Study: stabilizing secondary pressure

Problem

In a typical pressure reducing valve, the piston inside the valve is disturbed by the steam flow itself, causing the pressure on the secondary side of the valve to become unstable and deviate from the set value.

Solution

COSPECT uses a spherical piston to ensure accurate operation, unaffected by steam flow. As a result, the pressure on the secondary side of the pressure reducing valve is stable and rarely deviates from the set value.

Case Study: Reducing product defects

Problem

Rust, scale, and water droplets flowing in steam piping can adversely affect quality by sticking to the product.

Solution

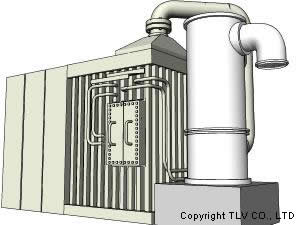

COSPECT has a built-in separator, screen (strainer), and steam trap.

Large rust and scale are blocked by the screen, while fine rust and scale that pass through the screen are forcibly separated by the separator and discharged with condensate. This prevents any adverse effects on production and quality.

Case Study: safety valve blow-off

Problem

Rust and scale flowing in the steam piping can interfere with the smooth movement of the piston and increase the pressure on the secondary side of the pressure reducing valve, causing the safety valve to blow.

Solution

COSPECT has a built-in separator, screen (strainer), and steam trap.

Rust and scale are forcibly separated by the separator and discharged with condensate, allowing the piston to continue smooth movement and preventing pressure buildup that could cause the safety valve to blow.

Case Study: simpler piping arrangement

Problem

Separators, strainers, and steam traps are installed separately, which not only complicates construction but also requires a large space for installation.

Solution

COSPECT has a separator, steam trap, and strainer built into the main unit, enabling easier installation and in a smaller space as one pressure reducing valve.