Fluid Control Equipment

PowerDyne® Disc-Type Steam Traps

P Series/HR Series/FP46UC

Air-insulated Jacket

In traps with a single-layer cap, adverse weather conditions and radiant heat loss can result in steam loss from rapid-cycling actuation. The TLV PowerDyne® series steam traps are equipped with an air-insulated jacket, giving resistance to environmental effects and minimizing unnecessary operation and steam loss.

Comparing the effect of external conditions by cap insulation

PowerDyne® Disc Trap

The TLV PowerDyne® series includes an air jacket for resistance to environmental conditions. The hardened valve trim also helps reduce wear and promotes reliable operation, effectively minimizing steam loss.

Conventional Disc Trap

In order to prevent air binding, some valve discs have a rough-ground surface or machined leakage path. These actions reduce sealing, increase steam loss, and can eventually lead to a costly blowing condition.

Effect of weather on steam loss

Mirror-polished Sealing Surfaces

Some valve discs include an air leak pathway or rough finish to prevent air binding. However, this can result in greater surface wear and steam leakage due to no-load actuation. The TLV PowerDyne® series solves this problem: the bimetal air vent ring* eliminates air binding and allows the hardened sealing surfaces to be mirror polished, resulting in a tight seal that saves steam.

* All models except HR150A, HR260A (due to superheat temperature limits), P21S ver. C and P46S

Bimetal Air Vent Ring*

Start-up time improvements enabled by automatic bimetal air venting

To reach full operating efficiency, initial air and cold condensate must be purged from steam lines quickly. PowerDyne®'s bimetal air vent ring* quickly and efficiently vents start-up air without binding, eliminating the need for manual blowdown.

* All models except HR150A, HR260A (due to superheat temperature limits), P21S ver. C and P46S

How the bimetal air vent ring operates

At room temperature, the C-shaped bimetal air vent ring contracts, rising along the valve seat skirt and forcibly lifting the disc valve off its seat. With the valve open, low temperature air and condensate that enters the trap can then be discharged.

When the temperature of incoming condensate rises, the bimetal air vent ring heats up, expands, and slips down the valve seat skirt. The force keeping the valve open is released and the trap can function normally.

Increased productivity by prevention of air binding

In PowerDyne® disc steam traps, initial air is automatically discharged by the thermostatic air venting design*, significantly reducing start-up time.

* All models except HR150A, HR260A (due to superheat temperature limits), P21S ver. C and P46S

With bimetal air vent ring

When air binding occurs

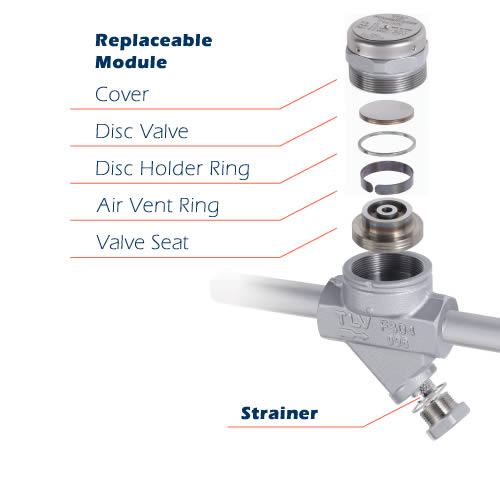

Inline replacement of normal wear parts, even for socket welded connections

Inline replacement is possible

When disc traps fail, a common practice is to replace the entire trap, not just the internals. Short service life results in high replacement costs.

TLV PowerDyne® disc steam traps have been engineered to save time and minimize maintenance costs. The replaceable module* design enables quick and easy inline repair of normal wear parts without having to replace the entire trap.

* All models except P46S and P21S ver. C

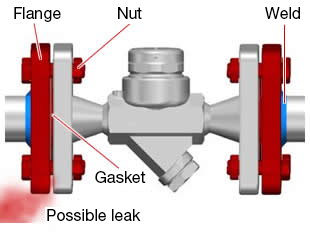

Advantages of socket welded connections

Reduce parts and work costs

In addition to the slightly higher cost of flanged products, each SW connection unit eliminates the need for two flanges, two gaskets, and at least eight sets of bolts and nuts.

Minimize potential leak locations

Welded connections can minimize the number of locations from which steam can leak.

Horizontal and vertical installation possible

Disc types are known for being able to be used on both vertical and horizontal piping with no problems. However even if we install on horizontal piping, we should avoid installing the trap upside down.