- Home

- Steam Resources

- Steam Theory

- Size Matters: The Guide to Equipment Connection Sizing

Steam Distribution

Size Matters: The Guide to Equipment Connection Sizing

Choosing Connection Sizes: Bigger is Not Always Better

When selecting equipment such as valves, pressure reducing valves (PRV), flowmeters, how do you decide on the nominal connection size? Ball valves are relatively straightforward and a 50 mm (2 in) ball valve can be used on a 50 mm (2 in) pipe. However, you may run into some problems installing a 50 mm (2 in) pressure reducing valve on a 50 mm (2 in) pipe. While general valves can be selected based on the pipe size, when selecting a PRV or flowmeter, they must be sized based on their operating flow range.

Let’s consider the COS-16 pressure reducing valve from TLV, which has a minimum adjustable flow of 5% of the rated flow rate (10% for 65 mm [3 in] and larger). This means if the rated flow is 1000 kg/h (2200 lb/h), the valve can adjust pressure for flow rates ranging from 50 to 1000 kg/h (110 to 2200 lb/h). However, issues may arise if the size of the PRV is matched to the piping as the flow rate could drop below the minimum flow. Under these circumstances, the PRV may not reliably maintain stable pressure. It's not uncommon for the connection size of PRVs and flowmeters to be far larger than actually required for the flow rate, because the valve connection size is simply matched to the pipe size. In such situations, flow rates outside the equipment's specified range cannot be accurately controlled or measured.

Unfortunately, one size does not fit all, and for control or measurement equipment, it's important to size them based on the actual flow and the equipment's flow range, rather than matching the pipe size. This approach ensures that the equipment operates effectively within its intended parameters.

Connecting Different Pipe Diameters with a Reducer

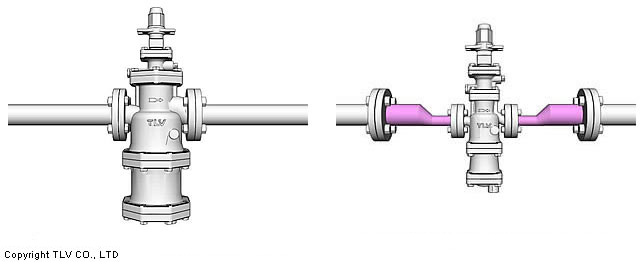

It's quite common to choose larger pipe diameters as a safety margin or planning for future expansion. The connection size of equipment may be smaller than the existing pipes when selecting based on the actual flow. This discrepancy necessitates the use of a pair of reducers – a fitting that enables connection to a smaller pipe diameter – to allow the equipment to be installed on the larger pipe. While this means more work is needed when installing, it is necessary to ensure accurate control and measurement. Additionally, some devices, such as flowmeters, require a specific length of straight pipe on both sides. When installing, please follow the instructions provided.

| |

| PRV with 50 mm (2 in) nominal size installed on 50 mm piping | PRV with appropriate connection nominal size installed on 50 mm (2 in) piping using a reducer |

Sizing example for a Pressure Reducing Valve

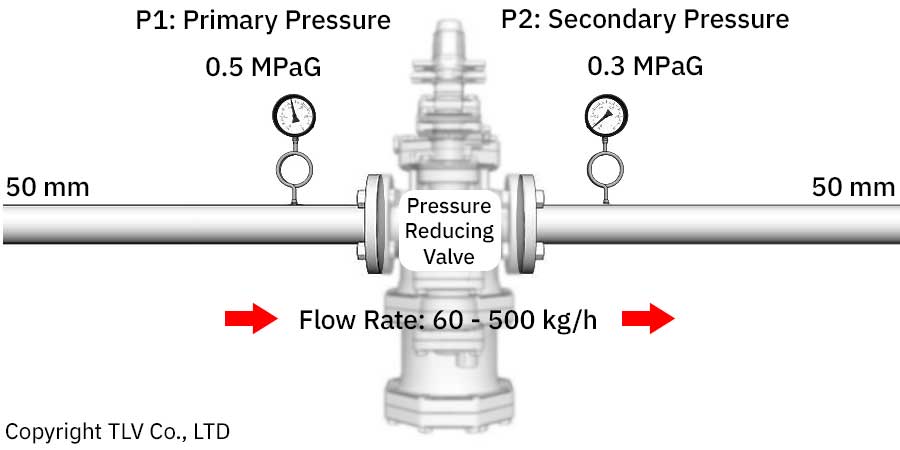

Let's size a PRV for a 50 mm (2 in) pipe with an operational steam flow of 60 kg/h (132 lb/h) to 500 kg/h (1100 lb/h).

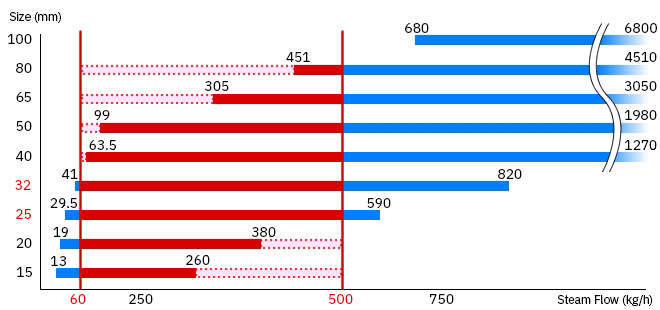

The diagram below shows the adjustable flow ranges for each size of a particular model of PRV when reducing from 0.5 to 0.3 MPaG (72.5 to 43.5 psig). The red section shows the operational steam flow range.

To cover the steam flow range of 60 kg/h (132 lb/h) to 500 kg/h (1102 lb/h), the PRV requires a connection size of either 25 mm (1 in) or 32 mm (1¼ in). A 50 mm (2 in) connection to match the piping will not cover the flow range of 60 kg/h (132 lb/h) to 99 kg/h (218 lb/h).

Sizing example for a flowmeter

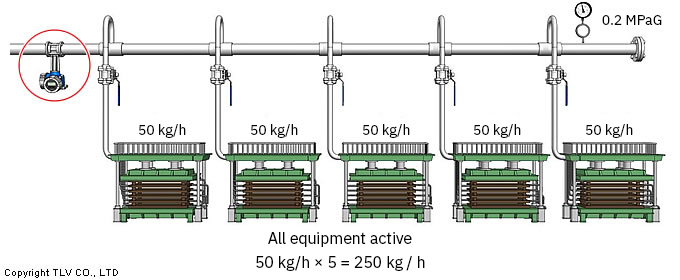

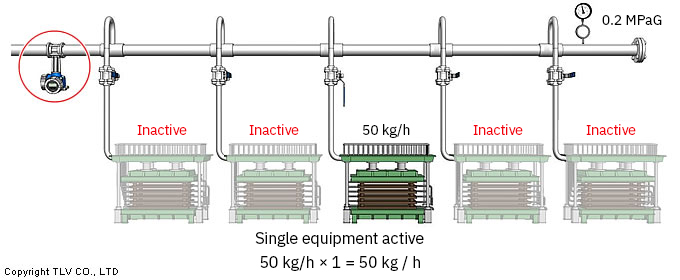

Consider a 50 mm (2 in) pipe supplying steam to five steam-using presses, each with an operational steam flow of 50 kg/h (110 lb/h). The equipment may operate individually or all at once. We are considering installing a flowmeter on this pipe, with a steam pressure of 0.2 MPaG (29 psig).

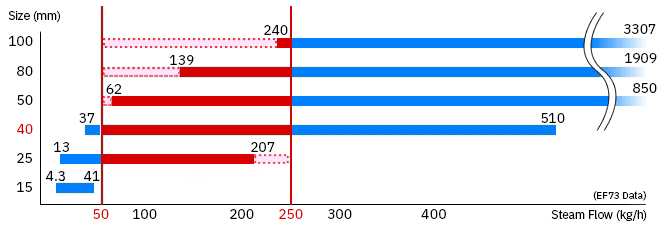

For this example, the red section shows the operational steam flow range against the flowmeters' measurable flow range by size as shown in the diagram.

As you can tell, a 40 mm (1½ in) flowmeter can measure a steam flow of 50 kg/h (110 lb/h) to 250 kg/h (551 lb/h). In contrast, if a 50 mm (2 in) flowmeter were chosen to match the pipe diameter, it would not be able to measure the flow when only one press is operating.

Selecting the right size for a flowmeter is often more complex than for a pressure reducing valve. This complexity arises mainly because the flow rate may not be known in advance, and a flowmeter is necessary to determine it. In these situations, a thorough assessment is required. The approach for such cases is explained in a future article.