- Home

- Steam Resources

- Steam Theory

- Steam System Accessories Part 2

Steam Trap Considerations

Steam System Accessories Part 2

Accessories Required for Maintenance

In "Steam System Accessories Part 1", we explained the accessories required for operation and for checking operation of the steam trap. In this article, we cover the accessories required for maintenance.

When installing a steam trap, valves must be installed at the trap inlet and outlet, and a bypass valve and strainer should be installed to facilitate maintenance.

Steam trap inlet valves

A valve must be installed on the primary side of the steam trap to temporarily close off the steam supply and allow disassembly and parts replacement.

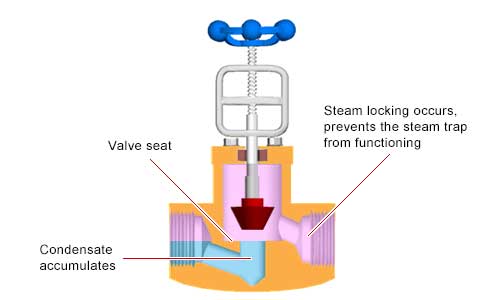

Let's consider the type of valve that should be used. As shown in the figure below, the valve seat of a ball valve is located near the center of the piping, so condensate can pool up to this point.

When condensate pools inside the valve, steam can become trapped between the inlet valve and the trap, causing steam locking and preventing condensate discharge. It is recommended to use a ball valve or gate valve with a straight flow path for the inlet valve in areas prone to condensate generation, to prevent condensate from backing up in the piping.

A globe valve can also be used with low amounts of condensate, when there is no danger of steam locking due to the valve.

Learn more about steam locking.

Steam trap outlet valves

Trap outlet valves are required for both individual steam traps and those discharging to a collector pipe. This is to temporarily close the discharge of steam and condensate from the trap outlet side, to allow for trap maintenance or replacement.

Unlike the inlet valve, the outlet valve does not affect the trap operation or condensate discharge even if condensate remains in the trap, so there are fewer restrictions on the type of valve that can be used.

Bypass valves

In addition to inlet and outlet valves, bypass valves are also necessary to perform maintenance of the trap during operation of the steam-using equipment. When the inlet and outlet valves are closed, condensate cannot be discharged through the trap. In this case, by opening the bypass valve and allowing steam and condensate to be discharged, the trap can be removed for maintenance or replacement, while the steam-using equipment continues to operate without interrupting the process or closing the steam line.

Globe valves are typically used to allow adjustment of the valve opening according to the condensate amount.

Bellows sealed valves are often used for globe valves to prevent gland leakage, for energy conservation and ease of maintenance.

For equipment that discharges a large amount of condensate and where steam locking is a problem, a ball valve or gate valve is recommended for the trap inlet valve

For main line applications where the condensate load is low and steam locking is not a problem, a globe valve can be used as the trap inlet valve.

Learn more about the different types of valves.

Strainers

Rust, scale and other foreign matter can flow into the trap and cause the trap to fail. A strainer is needed to prevent this. Some traps have a built-in screen, in which case it is not necessary to install a strainer.

However, TLV recommends the installation of a strainer if there is a lot of rust and scale due to aging piping or poor water quality, or if the screens built into the trap are difficult to clean.

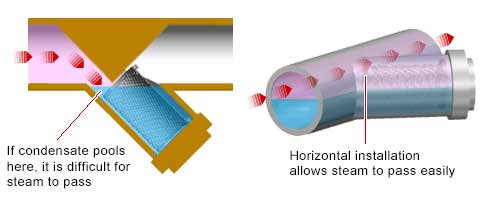

As shown in the figure, some strainers are prone to condensate pooling due to their shape, therefore horizontally installation is recommended to allow the unrestricted flow of steam.