- Home

- Steam Resources

- Steam Theory

- Insulating Traps

Steam Trap Considerations

Insulating Traps

Steam transport piping is insulated to prevent steam losses due to radiant heat. It is also important to insulate valves and pressure reducing valves having large radiant heat surface areas that are connected to this piping. What about steam traps?

Steam is supplied to the inlet of a steam trap, so the inlet piping should also be insulated to prevent radiant heat losses.

But is it OK to insulate all steam traps without regard to the conditions? Actually, no-there are some circumstances in which it is not acceptable. There are many different types of traps, and whether or not it is OK to insulate the trap depends on what type it is.

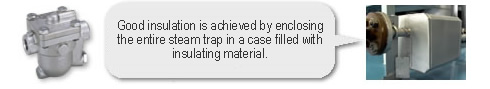

Traps that can be insulated without adverse effects

Float type

Because the valve opens and closes based only on the change in water level inside the trap, insulating the trap has no adverse effects whatsoever.

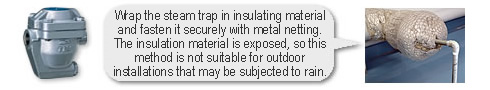

Traps that should only have light insulation

Bucket type

The buoyancy of the bucket is used to open and close the valve, but this happens in conjunction with the process of the steam condensing in the trap, so heavily insulating the trap may result in impaired operation.

Traps that should not be insulated

Disc type and thermostatic type

With these types of trap, the trap must cool down for the valve to open (‘the cooling of the trap’ is a necessary condition for the valve opening movement). If the trap is insulated, it is difficult for the trap to cool down, and the opening of the valve is delayed. This delay in valve opening causes condensate that should have been discharged to pool, so these types of trap must not be insulated.

As we can see from the breakdown of traps into these categories, only with float type traps is it acceptable to insulate the trap without regard to conditions. Care must be taken with all other types of traps, as over-insulating may lead to condensate pooling.

At the same time, care must also be taken that traps in the ‘should not be insulated’ group do not get too cold, as this results in the danger of the valve opening even in the absence of condensate, thus leading to large steam losses.

At the time of the oil crises some 30 years ago, there was talk in Japan of huge energy savings to be gained by placing an empty can over steam traps, and actually this idea provided a brilliant balance between not insulating at all and over-insulating. In fact, most modern-day disc traps come equipped with a cap that is similar to this empty can.

As we have seen, when insulating traps it is critical to do so only with an understanding of the trap’s characteristics.