- Home

- Products

- Filters

- Separator Filters

- Overview

Fluid Control Equipment

Separator Filters

SF1

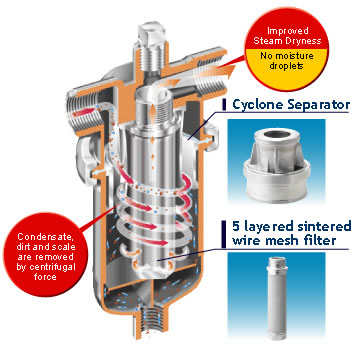

Construction

Cyclone Separator

Centrifugal force and gravity remove 98%* of condensate

Separation and removal of condensate enable the supply of dry, high quality steam.

* At flow velocities of 30 m/s or less.

Centrifugal force and gravity remove large dirt particles and scale

Preventing major sources of filter blockage from reaching the filter results in a longer service life.

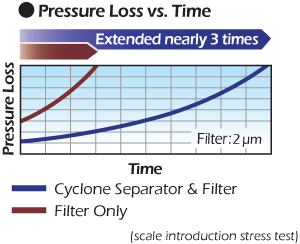

Maintenance cycle is nearly 3 times longer

Compared to a filter with no separator, the time between required maintenance is removed by nearly 3 times.

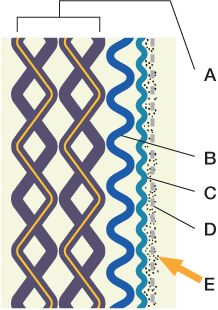

Five-layer sintered wire mesh filter

Effective cleaning allows repeated use

The five-layer sintered wire mesh filter catches small dirt and scale particles on the outer surface of the filtration layer. Compared to sintered metal powder, the wire mesh filter is easier to clean resulting in longer durability and reusability.

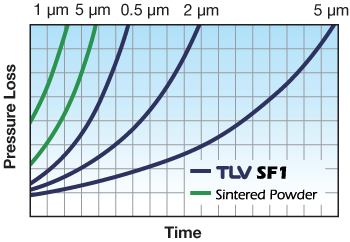

Lower pressure loss

TLV's sintered wire mesh filters provide a longer maintenance cycle than powder filters of the same grade. Therefore the decision to use a finer filter grade or a more compact filter becomes easier.

|

A: Reinforcement layers(woven wire mesh) B: Dispersion layer C: >Filtration layer D: Protective layer E: Dirt, scale |

|

TLV SF1 Sintered Wire Mesh Filter (Diameter: 40 mm; Length: 125 mm; Surface Area: 160 cm2) Sintered Powder Filter (Diameter: 60 mm; Length: 250 mm; Surface Area: 470 cm2) Stress Test Parameters

|

Clamp construction

Ferrule joint clamp facilitates easy cleaning.

All stainless steel construction

The body is made of corrosion-resistant CF8 stainless steel.