- Home

- Products

- Waste Heat Recovery

- Steam Condensing Heat Exchanger

Fluid Control Equipment

Steam Condensing Heat Exchanger

SR Series

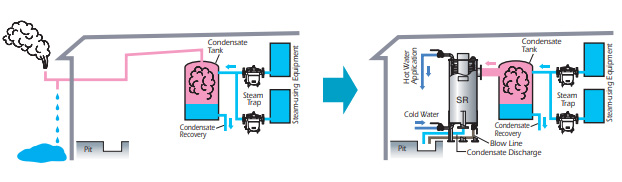

Eliminate “steam clouds” and recover heat energy as hot water

Hot water generated by SR series is suitable for cleaning/preheating water for production processes, bottle washing and other post-production cleaning applications. Unique structure that does not apply pressure makes recovery of atmospheric pressure steam possible.

Flash Steam and Waste Water Heat Exchangers Pamphlet (806 KB)

Benefits and Features

Energy savings via heat energy (waste steam) use

The heat exchange capacity is comparable to that of a sealed heat exchanger, enabling effective use of heat that would otherwise be discarded.

Large Degree of Freedom for Installation

The product can be easily introduced as it is an open-to atmosphere system free from the restrictions and regulations governing pressure vessels.

Application Areas

- Heat recovery from steam in processes to where pressure cannot be applied (Waste steam heat recovery from steamers, set machines, etc.)

- Treatment of re-evaporated steam from supply water/condensate tanks

- Improving work environment where steam clouds are generated around the plant

Product Details

| Model | Photo | Steam Inlet | Body/Heat Transfer Coil Material | PMO (MPaG) |

TMO (°C) |

Max. Steam Flow Rate (kg/h) | Specifications | Manual | |

|---|---|---|---|---|---|---|---|---|---|

| Body (Shell side) |

Coil (Tube side) |

||||||||

| SR-3 |  |

Flanged | Stainless (SUS304) |

0 | 1.0 | 100 | 300 | Specifications | Manual |

| SR-8 | Flanged | Stainless (SUS304) |

0 | 1.0 | 100 | 800 | |||

- PMO = Maximum Operating Pressure

- TMO = Maximum Operating Temperature

The latest version of each product's instruction manual can be found on this page.