Fluid Control Equipment

Bypass Blow Valves

BD800

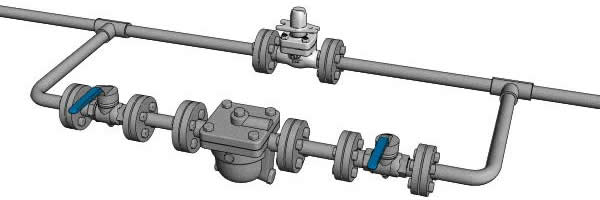

Valves that ensure reliable, high sealing performance after bypass blow.

Periodic maintenance of steam system is followed by blowdown on bypass lines by supplying high pressure steam at start-up. However, globe valves often installed on bypass lines are commonly susceptible to internal leakage as the build-up of dirt and scale and the erosion of valve trim prevent the valve from closing completely. The BD800 was developed to eliminate these problems.

Bypass Blow Valve Pamphlet (1481 KB)

Benefits and Features

Prevents Leakage

Gland packing proven in high pressure applications prevents external leakage.

Scale Removal Function

The inline scale removal function allows the removal of scale and dirt by operation of the valve, preventing clogging and reducing wear on the valve seat. See the instruction manual for details.

Highly Durable

Highly durable materials resistant to erosion and corrosion.

Easy Inline Maintenance

Gland packing, valve stem, valve seat, and gaskets replaceable inline.

Application Areas

- High temperature and high pressure applications, such as steam trap bypass lines.

- Bypass or other lines: for blowdown or elimination of steam locking

Product Details

| Model | Photo | Connection | Size | Body Material | Port | Operation | PMO (MPaG) | TMO (°C) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| BD800 |  |

Screwed | 15 20 25 |

Stainless Steel (ASTM A182 Gr.F304) | Reduced Port | By hand | 6.5 | 425 | Specifications | Manual |

| Socket Welded | ||||||||||

| Flanged |

- PMO = Maximum Operating Pressure

- TMO = Maximum Operating Temperature

The latest version of each product's instruction manual can be found on this page.