- Home

- Steam Resources

- Steam Theory

- Why Save Energy?

Energy Efficiency

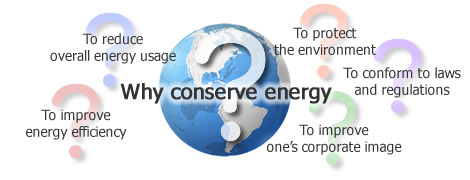

Why Save Energy?

There are numerous reasons why plants, firms, and people around the world are trying to save energy. Some reduce their energy use to lower energy costs and improve production capability, while others are driven by environmental concerns, regulations, or the desire to improve their corporate image.

This article begins by reviewing the recent history of global energy conservation initiatives, and then examines some topics that plant management may want to consider when planning a comprehensive, proactive, and sustainable energy conservation strategy.

A Brief History of Global Energy Conservation Initiatives

The rise of steam machinery in the 18th century industrial era led to a heightened interest in using energy in the most efficient manner possible, and to the development of the field of mechanical engineering, which at the time was largely devoted to developing more energy-efficient technologies. James Watt, father of the steam engine, was a mechanical engineer who incorporated physics into his efforts to develop a more efficient engine. The research of Sadi Carnot, Rudolf Clausius, and Lord Kelvin led to the development of the second law of thermodynamics, which states that there is an upper limit to the conversion of heat to work.

The discovery of new fuel sources and development of electrical power in the 19th century led to the production of increasingly efficient engines. The development of small-scale electrical motors, pioneered by Nikola Tesla, led to the invention of innumerable small-scale electronic devices that were far more efficient than combustion-driven machinery.

In the early 20th century, the development of variable-speed motors increased the capabilities and efficiency of electrical devices. As electrical machinery became ubiquitous in industry, factories' production increased, and so too did pollution from factories, cars, and power plants.

To combat this problem, governments around the world started taking steps to regulate the use of energy in industry. Japan was one of the first nations to act, with the government implementing Heat Management Regulations in 1947. These regulations called on industries to implement more efficient heating processes, reduce heat loss, and collect and reuse used heat sources where possible. In the US, deteriorating air quality in some major cities such as Los Angeles led to the implementation of the Air Pollution Control Act in 1955, which regulated industrial emissions. In the UK, smog from factories became a major health concern, and in response the government implemented the Clean Air Act in 1956. Other nations also introduced similar regulations in this era.

The global energy crises of the 1970s, environmental disasters, and climate change spurred governments to introduce stricter energy regulations for industry. Their regulations, as well as the desire to reduce energy costs, led to substantial efficiency improvements in industrial energy use during the 1970s and 80s in particular. Technological developments also made consumer electronics and transportation more energy efficient. More recently, global frameworks promoted by the United Nations Framework Convention on Climate Change (notably the Kyoto Protocol and the Paris Agreement) have set strict emissions targets for nations around the world, and encouraged participating nations to implement stringent environmental regulations.

Reasons for Saving Energy

For industrial plants and businesses, there are four main reasons for saving energy:

To improve production by optimizing steam quality/product heat

Backpressure in return lines from open bypasses or blowing traps can restrict production rates.

Steam or condensate wasted to grade elevates the need for additional make-up water. Make-up water requires heating with diverted boiler steam that could otherwise have been used for process heat.

Diverted or lost steam/condensate can have the effect of lowering boiler steam temperature, which has a direct effect on the logarithmic mean temperature difference (LMTD) between the hot and cold sides of the heat transfer. Steam energy use should be optimized not only to simply lower energy cost, but also as part of a strategy to optimize production value.

To improve competitiveness by reducing costs

To safeguard against depletion of fossil fuel reserves

To reduce the burden on the environment

To be socially responsible

When steam use is not optimized, three main issues that decrease production can develop:

As energy cost makes up a large portion of a company's operating expense, reducing energy use is an effective method to raise a company's profit due to its direct impact on the bottom line.

New forms of energy generation using renewable resources have been developed, and researchers are developing more efficient ways of generating renewable energy each year. Still, non-renewable resources are finite. Recently, new methods of extracting oil and/or natural gas have been developed, including cross-drilling, removing oil from oil sands, steam-assisted-gravity-drainage (SAGD) procedures, and drilling wells in Sakhalin Island to depths exceeding 12,000 meters [40,000 feet]. If these severe extraction methods are already being used today, what can be expected 100 years from now? Currently, it is estimated that all exploitable petroleum and liquid natural gas (LNG) on earth can be depleted in approximately 50 years, and coal in just over 100 years. So, regardless of the impact of renewable energy, it is crucial to use natural resources as efficiently and sparingly as possible for the sake of our planet and future generations who depend on having energy sources available to them.

The progression of climate change has made urgent action to reverse its effects a global necessity. In particular, reducing greenhouse gasses such as CO2 through renewable energy development and conservation has become a vital task for nations, businesses, and individuals.

Industrialization has led to improved technologies and readily-available goods that have made our lives easier, but it has also created environmental problems that are affecting the entire planet. Consumers now expect firms to be responsible and take the lead in mitigating future and rectifying current environmental problems. As part of corporate social responsibility (CSR) practices, companies are expected to reduce the environmental impact of their business practices, products, and services, and release information about energy use, carbon emissions, and environmental impact. Major corporations have found improving their environmental footprint to be an effective way of improving their brand image and increasing public support for their local operations.

Corporate Energy Conservation Starts at the Top!

Managers can refer to local guidelines and regulations on energy use and waste reduction as a starting point when designing an energy conservation strategy. They can also establish specific targets for reducing electricity, fuel usage, and cost through implementation of a proactive, sustainable energy management program. These initial goals enable plants to work together to assess their energy saving progress, and can go a long way to achieving success.

Effective energy management starts at the top, and it is the role of management to promote and require achievement of realistic energy conservation goals that all employees can work towards together.

TLV's consultants and engineers can help you design an effective strategy for conserving energy.

Contact us for more information: