蒸気のことならテイエルブイ

- North America

- Latin America

- Europe

- Middle East

- Asia

- Oceania

- Other Regions

All-In-One Tool for Daily Inspections, Wherever the Job Takes You

All-In-One Tool for Daily Inspections, Wherever the Job Takes You

Automatically diagnose steam trap and valve operation, inspect bearings and a range of equipment. Tag and manage locations, record and share custom inspection data in one simple workflow. Certified for safe use in hazardous areas.

One Device for Daily Inspection of Steam Traps, Valves, Bearings, and More

Automatically assess steam trap and valve condition. Capture vibration, temperature, and acoustic data from other equipment.

Designed for hazardous locations, with IP54 dust protection and explosion-proof certification. A mobile app makes data sharing and reporting simple.

One Device for Daily Inspection of Steam Traps, Valves, Bearings, and More

Automatically assess steam trap and valve condition. Capture vibration, temperature, and acoustic data from other equipment.

Designed for hazardous locations, with IP54 dust protection and explosion-proof certification. A mobile app makes data sharing and reporting simple.

Pocket TrapMan® PT3 – 5 Core Functions

Asset Tagging

Temperature Measurement

Audio Monitoring

Vibration Measurement

Mobile App Integration

Simplify Daily Inspections with Pocket TrapMan®

Reliable Inspection Results

Automatically evaluates the condition of steam traps and valves, delivering consistent inspection results without specialized training.

All-in-One Solution

Measure ultrasound, temperature, and vibration with a single device, reducing inspection time and increasing efficiency.

Create Reports on the Spot

Capture and share inspection data instantly through the mobile app, keeping teams aligned and workflows moving.

Safe for Hazardous Areas

Intrinsically safe design enables safe operation in hazardous environments.

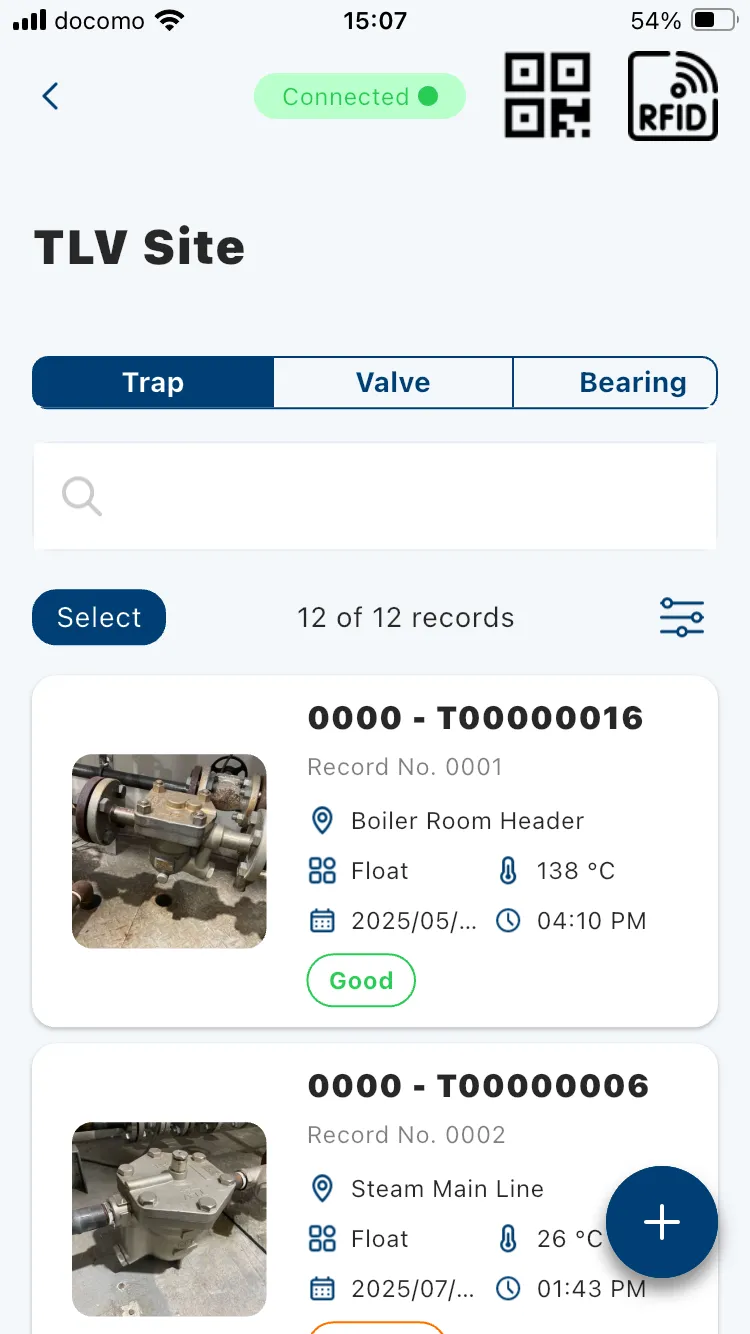

CMRecorder™

Collects and manages all field data captured with Pocket TrapMan® PT3,

supporting the entire inspection workflow from onsite diagnosis to reporting.

Smart Data Management

Condition Monitoring Recorder

Create reports, share findings, and manage historical records on a single platform with the CMRecorder™ app.

After inspections, PT3 wirelessly transmits the collected data to CMRecorder™, where it is securely stored and ready for analysis.

With just a few taps, CMRecorder™ transforms your stored data into clear, professional reports, helping you make faster, more informed maintenance decisions.

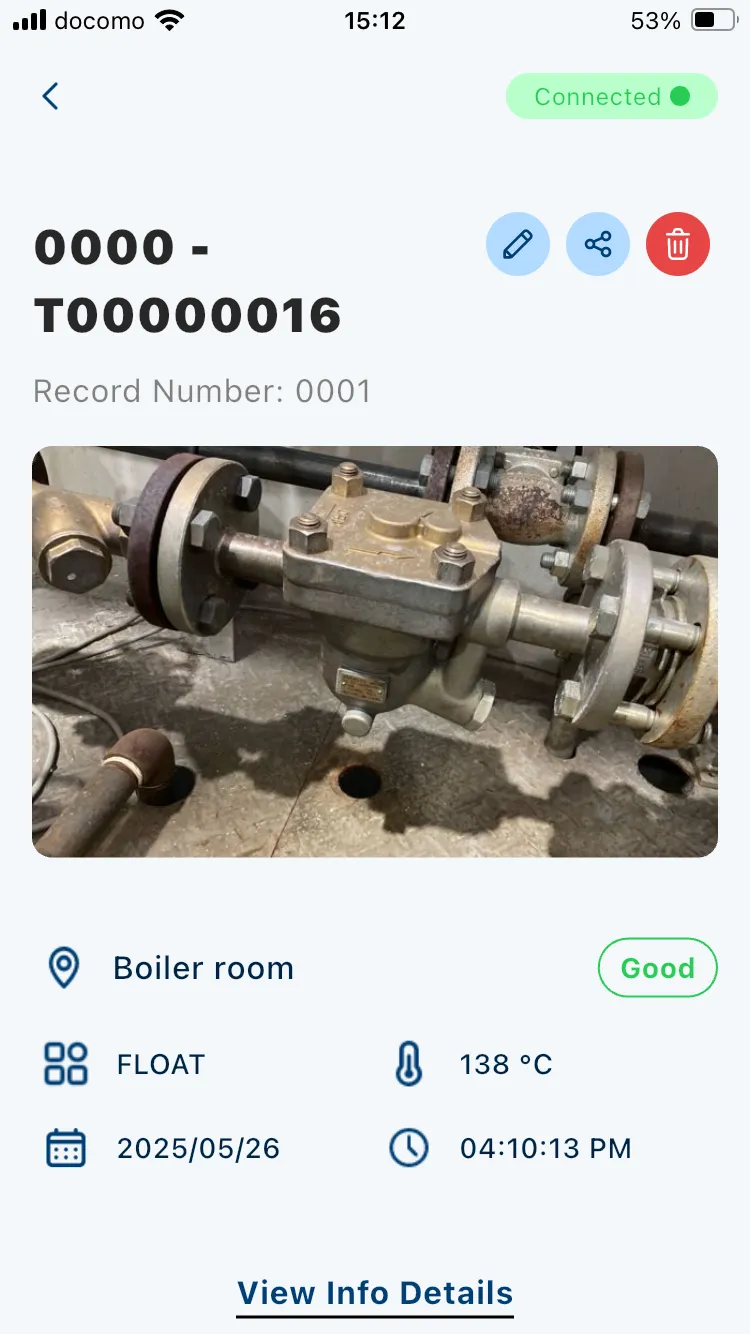

Instant Record Retrieval

Pull up past inspection records via RFID or QR code.

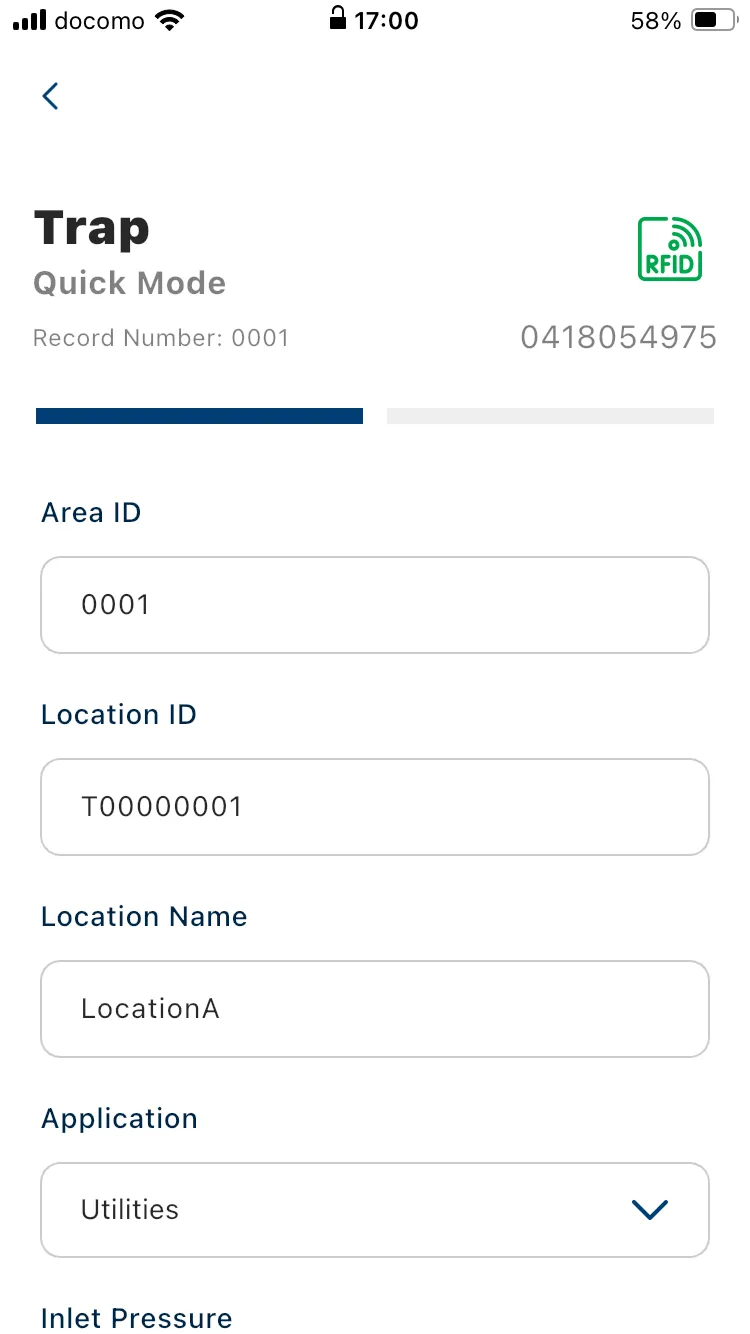

Capture All Findings

Measurements, photos, installation details, comments, and more.

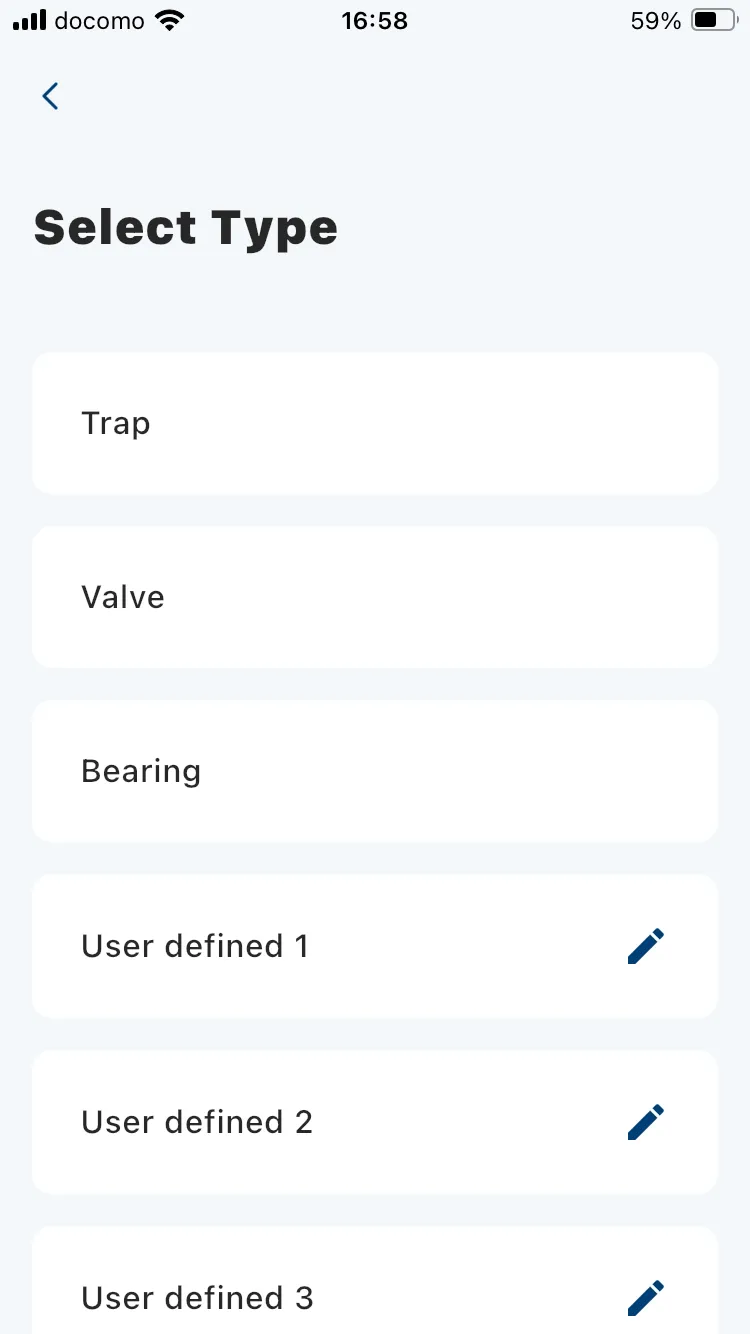

Customized Data Fields

Add up to three user-defined measurement types.

Accumulate Inspection Data

Inspection data from daily checks is stored over time for easy review.

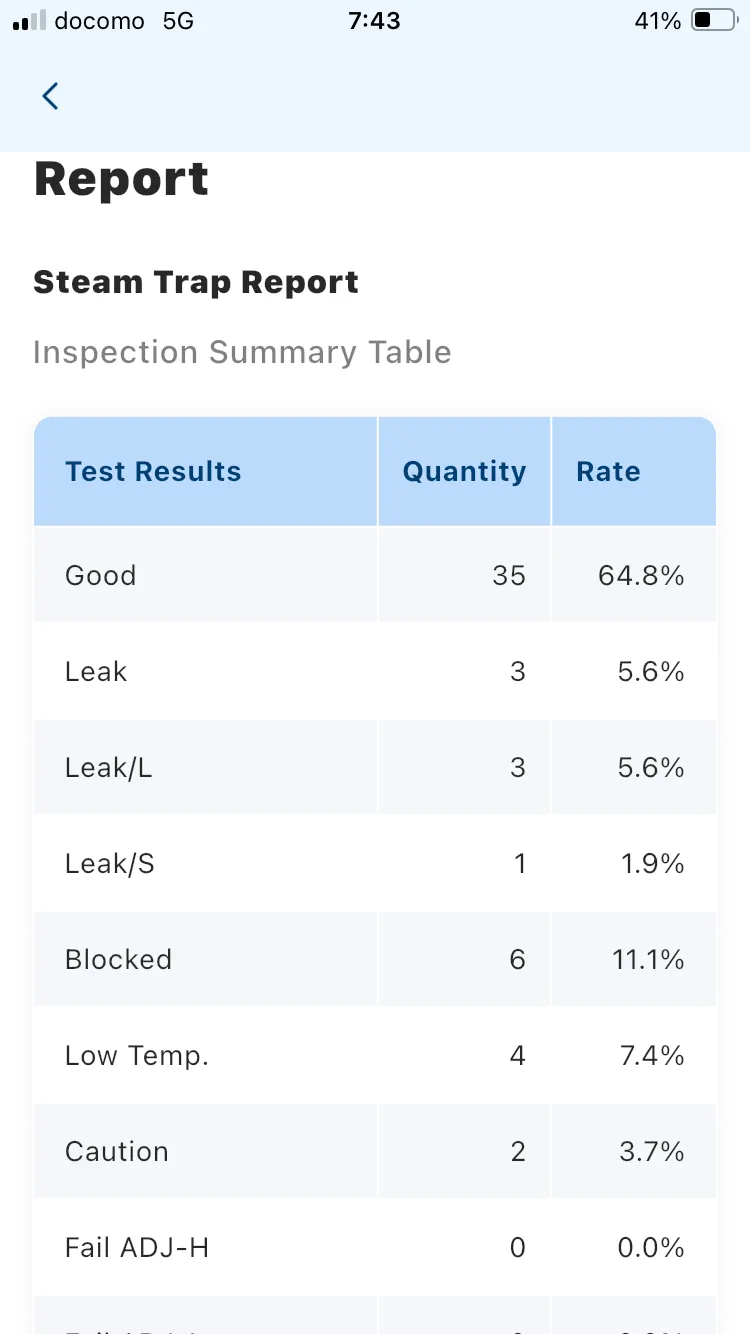

Create and Share Reports

Automatically compiles inspection results into clear, easy-to-read reports.

Data Export for Analysis

CSV for CMMS, BI, or other analytics platforms, or PDF for quick review.

Capture every detail that matters

Go beyond raw measurement data. Easily store photos from the field, operating conditions, pressure, installation locations, and technician comments—all neatly organized with each inspection record.

Custom fields to match your site

With customizable User Defined fields for location data, you can label measurement data using names that make sense on your site. Register up to three custom fields to reflect actual equipment layouts and inspection practices.

From raw data to actionable reports

Inspection results are automatically aggregated and transformed into clear, shareable reports. Export data in CSV or PDF format to streamline steam trap management, reporting, and internal communication.

Get in Touch

Our team is here to help with pricing or any questions you may have about PT3.

Applications

Practical use cases for inspection and maintenance across your plant.

Steam Trap Diagnosis

Identify early signs of steam trap malfunction using surface temperature and ultrasound, helping prevent energy loss and unplanned process stoppages.

Valve Condition & Leak Detection

Use surface temperature and ultrasound to detect leaks in bypass and inlet/outlet valves on steam and air lines.

Rotating Equipment Monitoring

Detect bearing wear and abnormal operation using ultrasound and vibration measurements. Ideal for equipment without permanent monitoring.

Temperature/Ultrasound Inspection for Piping

Inspect piping with surface temperature and ultrasound to identify leaks and heat loss, enabling energy saving opportunities.

Water tank temperature measurement

Measure surface temperature on hot water and condensate tanks to verify internal condition and sensor accuracy for early detection of abnormal operating conditions.

Brochure and Specifications

Get technical specifications and feature information in one easy-to-understand document.

Product Specifications

Specifications

Communication Specifications

Sensor Specifications

Environmental Specifications

Explosion-Proof Specifications

PT3 is available in region-specific models, each compliant with the explosion-proof standards required for safe operation in your area. Please make sure you are purchasing the correct model for your intended location of use.

App Specifications

Get in Touch

Our team is here to help with pricing or any questions you may have about PT3.