Principles of the Steam Compressor System

The steam compressor recovers low-pressure steam leftover from various processes and pressurizes it by mixing it with high-pressure motive steam. The result is low/mid-pressure steam that can be reused in another process.

As high-pressure and low-pressure steam mix, the pressure reducing valve responds to fluctuations in secondary pressure and adjusts the valve opening accordingly, regulating the steam flow.

Product combinations and features

By combining a high-efficiency ejector with a control valve with built-in cyclone separator, condensate recovery pump, flush tank, etc., the system can meet various requirements such as installation in explosion-proof areas and high-precision control in high-pressure areas. TLV can also provide support for selection, system design, and commissioning.

TLV can engineer a system suited to your needs based on a site survey, and adjust the system through commissioning to ensure that it operates as designed.

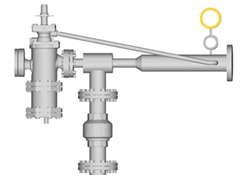

Atmospheric pressure steam recovery system

Self-actuated control valve COS

- Mechanical control

- High-precision pressure control

- Built-in separator

Non-electric Condensate Recovery Pump System Package

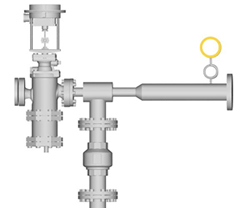

Pressurized condensate recovery system

Pneumatic control valve CV-COS

- Reliable control

- PID control

- Built-in separator

Flash vessel FV

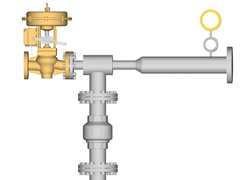

Condensate recovery system for high pressure ranges

Pneumatic control valve CV10

- High pressure

- Precise pressure control

- PID control

- Programmable control

Condensate Recovery Pump CP-N