- Home

- Products

- Steam Traps

- Free Float® Steam Traps (Medium/High Pressure)

Fluid Control Equipment

Free Float® Steam Traps (Medium/High Pressure)

JH Series

Mid to high pressure use, up to 12 MPaG

The JH series offers the three most important features needed in steam traps for steam-using equipment: a large condensate discharge capacity, powerful automatic air venting, and the ability to drain condensate in high pressure / temperature applications.

The use of special construction materials also makes this series perfect for processes requiring cast steel valves, even if pressure isn't of particular concern.

Free Float® Steam Trap Series Pamphlet (1439 KB)

Benefits and Features

Improved Efficiency of Heating Equipment

The Free Float® rises and sinks as the flow of condensate fluctuates, opening the valve to discharge condensate and closing off the valve when steam enters.

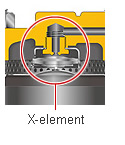

The built-in X-element (model names including 'X') functions as an air vent, discharging both cool and hot air. As a result, the steam chamber inside the equipment contains only steam, which allows the equipment to achieve optimized heating performance.

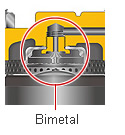

The built-in bimetal (model names including 'B') functions as an air vent, discharging initial cold air for rapid start-up.

Long Service Life, Excellent Durability

The spherical Free Float® rotates during operation, allowing any point on its surface to act as the valve seal and thus ensuring long service life.

Protects Equipment

'Fail Open' Design: The X-element is designed to fail open so that the valve remains open even in the event of failure.

Also for Use on Mid/High-Pressure Main Lines

The JH7 series employs the same 3-point seating construction found in products for use on main lines. The float is held tightly against the valve opening even under small condensate loads such as in superheated steam lines, so no steam is allowed to escape.

Application Areas

JH-X type

- For steam processes up to 3.2 MPaG that require the discharge of initial air and high temperature air

Particularly for processes with batch operations and where condensate removal is difficult - Employs an automatic air vent (built-in X-element) that rapidly removes both cold and hot air

JH-B type

- For steam processes over 3.2 MPaG that require the discharge of initial air

- Particularly for high temperature, high pressure steam mains and steam processes

- Employs an automatic air venting feature (built-in bimetal)

JH-P type

- For steam mains and steam processes over 4.6 MPaG

- Particularly for processes with extended, continuous operation and minimal amounts of entrained air

- Socket weld or screwed connection available

Product Details

| Model | Photo | Connection | Body Material | PMO (MPaG) |

TMO (°C) |

Discharge Capacity (kg/h) |

Specifications | Manual |

|---|---|---|---|---|---|---|---|---|

| JH3S-X |  |

Screwed, Flanged, or Socket Welded |

Cast Stainless Steel (ASTM A351 Gr.CF8) | 3.2 | 240 | 630 | Specifications | Manual |

| JH3S-B | 350 | 450 | Manual | |||||

| JH5RH-B |  |

Socket Welded | Cast Steel (ASTM A216 Gr.WCB) | 8 | 425 | 125 | Specifications | Manual |

| Flanged | ||||||||

| JH5RH-P |  |

Flanged | Cast Steel (ASTM A216 Gr.WCB) | 8 | 425 | 125 | Specifications | Manual |

| Socket Welded | ||||||||

| JH5RL-B |  |

Flanged | Cast Steel (ASTM A216 Gr.WCB) | 4.6 | 425 | 710 | Specifications | Manual |

| Socket Welded | ||||||||

| Screwed | ||||||||

| JH5RL-P |  |

Flanged | Cast Steel (ASTM A216 Gr.WCB) | 6.5 | 425 | 710 | Specifications | Manual |

| Screwed | ||||||||

| Socket Welded | ||||||||

| JH5RL-X |  |

Flanged | Cast Steel (ASTM A216 Gr.WCB) | 3.2 | 240 | 1000 | Specifications | Manual |

| Screwed | ||||||||

| Socket Welded | ||||||||

| JH5SL-X |  |

Screwed Flanged or Socket Welded |

Cast Stainless Steel (ASTM A351 Gr.CF8) | 3.2 | 240 | 1000 | Specifications | Manual |

| JH5SL-B | 4.6 | 425 | 700 | Manual | ||||

| JH5SH-B | 6.5 | 425 | 170 | |||||

| JH7.2R-B |  |

Socket Welded | Cast Steel (ASTM A216 Gr.WCB) | 4.6 | 425 | 5,700 | Specifications | Manual |

| Flanged | ||||||||

| JH7.2R-X |  |

Socket Welded | Cast Steel (ASTM A216 Gr.WCB) | 3.2 | 240 | 6,000 | Specifications | Manual |

| Flanged | ||||||||

| JH7.5R-B |  |

Socket Welded | Cast Steel (ASTM A216 Gr.WCB) | 4.6 | 425 | 13,000 | Specifications | Manual |

| Flanged | ||||||||

| JH7.5R-X |  |

Socket Welded | Cast Steel (ASTM A216 Gr.WCB) | 3.2 | 240 | 13,800 | Specifications | Manual |

| Flanged | ||||||||

| JH7RH-B |  |

Socket Welded | Low Alloy Cast Steel (ASTM A217 Gr.WC9) | 10 | 425 | 610 | Specifications | Manual |

| Flanged | ||||||||

| JH7RH-P |  |

Socket Welded | Low Alloy Cast Steel (ASTM A217 Gr.WC9) | 12 | 530 | 445 | Specifications | Manual |

| Flanged | ||||||||

| JH7RL-B |  |

Screwed | Cast Steel (ASTM A216 Gr.WCB) | 4.6 | 425 | 3,800 | Specifications | Manual |

| Socket Welded | ||||||||

| Flanged | ||||||||

| JH7RL-X |  |

Screwed | Cast Steel (ASTM A216 Gr.WCB) | 3.2 | 240 | 4,080 | Specifications | Manual |

| Socket Welded | ||||||||

| Flanged | ||||||||

| JH7RM-B |  |

Socket Welded | Cast Steel (ASTM A216 Gr.WCB) | 6.5 | 425 | 770 | Specifications | Manual |

| Flanged | ||||||||

| JH8R-B |  |

Socket Welded | Cast Steel (ASTM A216 Gr.WCB) | 4.6 | 425 | 26,000 | Specifications | Manual |

| Flanged | ||||||||

| JH8R-X |  |

Socket Welded | Cast Steel (ASTM A216 Gr.WCB) | 3.2 | 240 | 26,000 | Specifications | Manual |

| Flanged |

- PMO = Maximum Operating Pressure

- TMO = Maximum Operating Temperature

The latest version of each product's instruction manual can be found on this page.

Video of Free-Float® Steam Trap in Action

- This video was filmed using a steam trap with a window added for demonstration purposes.

- There is no sound for this video.