Fluid Control Equipment

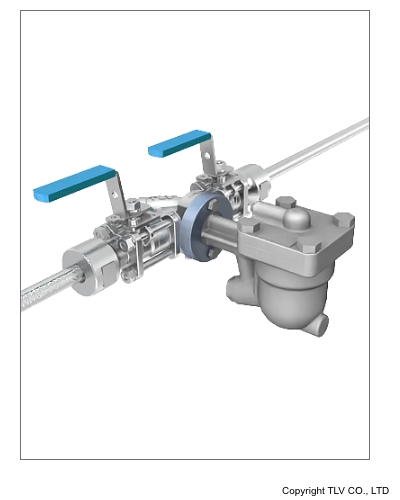

Steam Trap Stations

QS10/QS18 Series

QuickStation® Benefits

Compact, reliable, all-in-one design

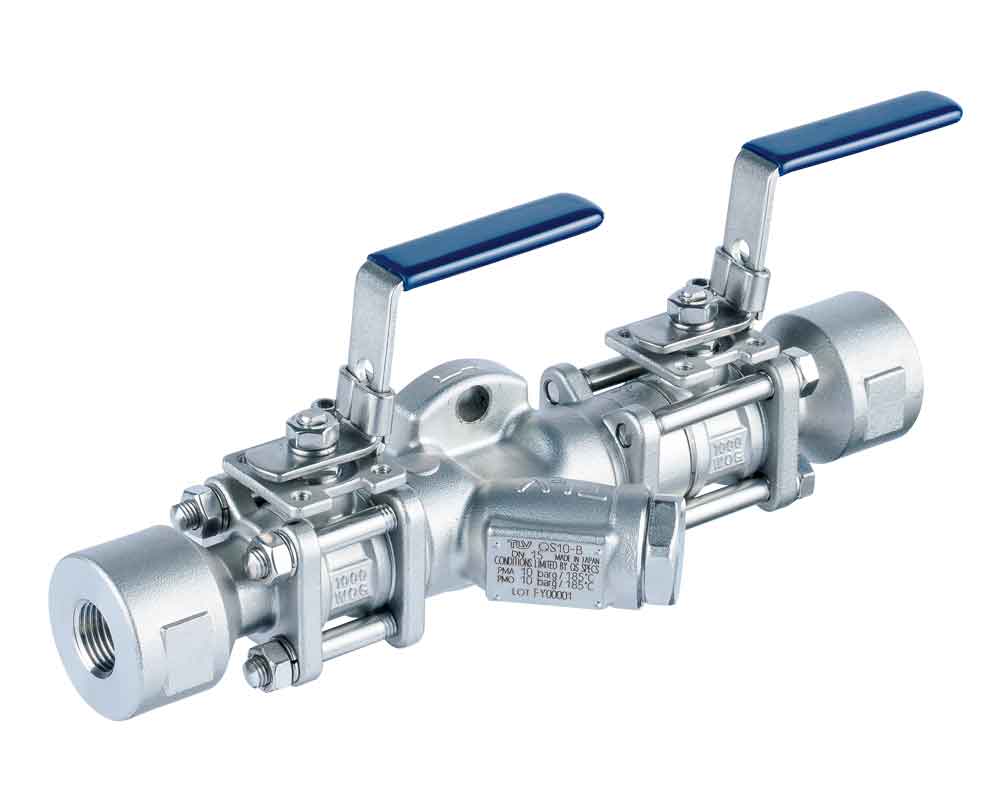

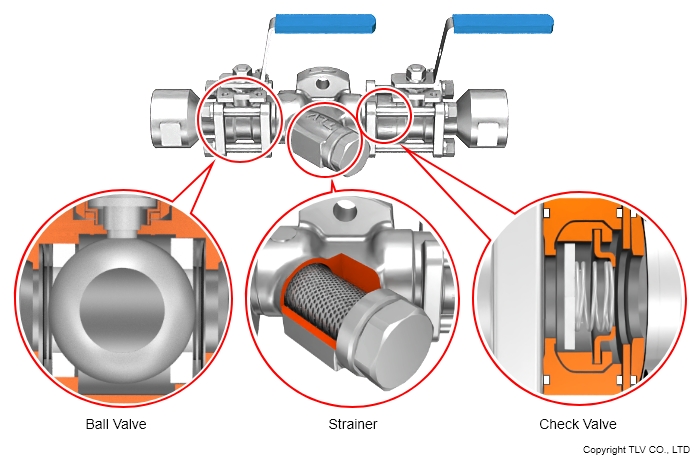

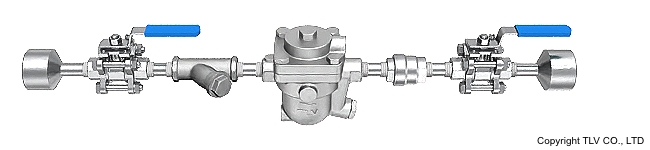

QuickStation® is an all-in-one steam trap station in stainless steel for durability and corrosion resistance. This all-in-one design is key to delivering the highest performance and reliability in a compact package.

Featuring single or double ball-type isolation valves, a removable strainer, and a spring-type check valve, the QuickStation® combines all the standard components of a steam trap station into a space-saving configuration. Furthermore, steam trap units can be replaced in minutes, without needing to disassemble the station or remove unions or piping.

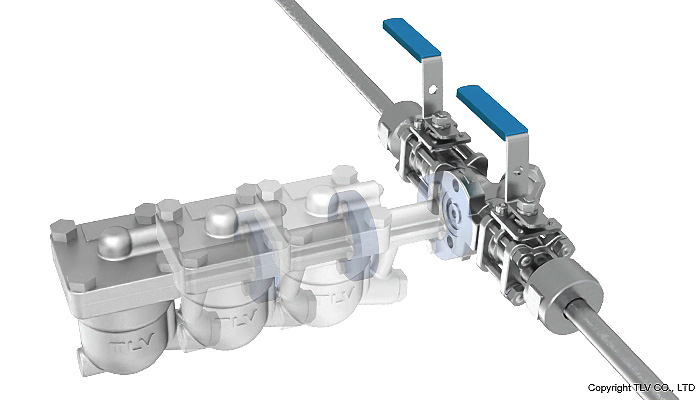

QuickStation® is compact

QuickStation® enables more compact installation of steam trap stations than conventional assembly of individual components.

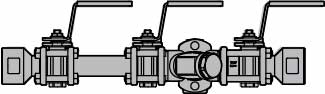

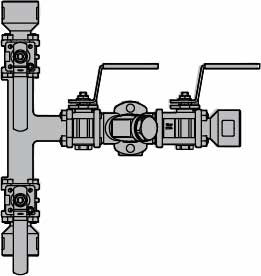

Horizontal or vertical installation

Universal connector enables horizontal and vertical installation.

|

|

Horizontal Piping | Vertical Piping |

Simple trap selection and installation

Steam traps can be installed in just a few minutes, reducing production downtime. With TLV's precision-engineered range of steam traps for a wide variety of uses, your application can operate at optimal conditions. By simplifying installation, replacement, and maintenance, these steam traps help resolve issues quickly, minimizing energy loss and enhancing energy efficiency.

Compatible steam trap models

TLV offers QuickStation® compatible steam trap units for various steam applications, from process use to installation on steam lines.

Selecting the right steam trap for your application helps deliver the best possible performance. If you are unsure of the right steam trap selection, consult with TLV's steam specialists or your local TLV representative.

Steam Trap Unit Specifications*1

| Model | J32-X | S1NL/S1NH | S3 | L21 | P46UC |

|---|---|---|---|---|---|

| Steam Trap Type | Free Float® | Free Float® | Free Float® | Thermostatic | Thermodynamic |

| PMO (MPaG) | 3.2 | 2.1 | 2.1 | 2.1 | 4.6 |

| TMO (℃) | 240 | 220/400 | 400 | 235 | 425 |

| Max Discharge Capacity*2 (kg/h) | 670 | 200 | 215 | 760 | 740 |

| Trap Image |  |  |  |  |  |

- *1: For more information, see the QuickTrap specifications data sheet for the steam trap employing the desired trap unit (trap unit - QuickTrap data sheet): J32-X - FJ32-X; S3 - FS3; L21 - FL21/FL32; P46UC - FP46UC. Contact TLV for details on S1NL/S1NH.

- *2: Capacities shown here will vary depending on orifice numbers, type of X-element and/or pressure differential.

Flexible configuration for maximum reliability

QuickStation® is available with either single or double upstream/downstream isolation valves and multiple piping arrangements.

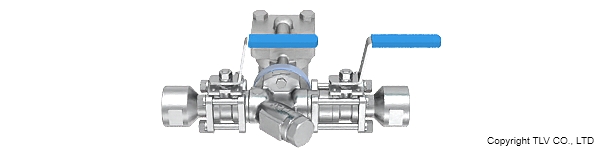

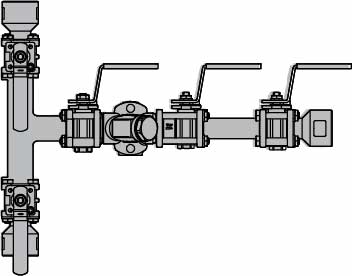

QS10-B, QS18-B with single upstream/downstream isolation valve |  QS10-D, QS18-D with double upstream/single downstream isolation valve |

QS10-T, QS18-T with double upstream/single downstream isolation valve in a tee configuration |  QS10-TD, QS18-TD with double upstream/downstream isolation valves in a tee configuration |

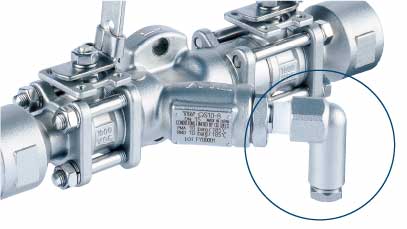

Optional blowdown valve

Elbow-type BD2 blowdown valve available for safer condensate blowdown and scale removal.

Difference between QuickStation® models

QuickStation® is available in two models, QS10 for general use on steam applications, and QS18 for higher temperatures and pressures. QS18 also complies with FDA, USP, EC 1935/2004 and other regulations concerning use in food, beverage, pharmaceutical, and similar clean steam processes. Note the different handle color to distinguish the two models.

|

|

QS10-B | QS18-B |