- Home

- Products

- Steam Traps

- Clean Steam Traps

- Overview

Fluid Control Equipment

Clean Steam Traps

LV6/LV6-HC/LV6D Series

Prevents Condensate Accumulation

Utilizes a special X-element to prevent condensate from pooling inside the trap

The LV6 series uses a special X-element, and the LV6-SF/LV6-P, in particular, uses an innovative free-draining X-element with a large orifice. This free-draining configuration prevents condensate from pooling in the element as well as in the trap body, making it easy to clean.

The orifice of the LV6 series is at the bottom of the trap, making it difficult for condensate to pool inside the trap body.

Free-draining X-element

with a large orifice in the lower body

(LV6-SF/LV6-P)

Clamp connection at the joint allows for easy disassembly and cleaning

Clamps enable easy disassembly and cleaning of the trap interior.

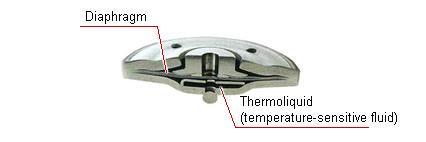

What is an X-element?

The X-element is comprised of a valve and a diaphragm that transmits the force of a thermoliquid (temperature-sensitive fluid). When surrounded by steam, the valve is closed. When condensate, air or other non-condensable gases are present, the valve is open. It can also discharge high temperature non-condensable gases, something bimetal air vents are unable to do. This is made possible due to the special properties of the thermoliquid.

Thermoliquid, like water, is liquid when kept under a certain pressure and temperature, and expands to become a gas when its temperature rises above a certain point. The temperature at which it becomes a gas is approximately 6°C (22°C for air vents) lower than the temperature at which water becomes steam.

So when it is surrounded by steam, the thermoliquid is a gas and the chamber containing the thermoliquid expands and pushes on the diaphragm. This causes the gap between the valve and the valve opening on the diaphragm to close.

In contrast, when the area around the X-element is at a low temperature (when it is either condensate or air), the thermoliquid is in the liquid phase and the valve is not being pushed closed, so condensate and air are discharged from the gap between the valve and the valve opening.

Note: the standard X-element type is also available, which operates (opens and closes) at 6°C below saturated steam temperature.

Under Normal Operation

"Fail Open" Safety Feature

Fail safe features are necessary in quality precision instruments. TLV therefore designed the X-element in such a way that the valve remains in the open position ('fail open' safety feature ) in the event the diaphragm ruptures.

If a steam trap fails, the valve may either remain open (blowing) or it may remain closed (blocked). If the valve remains closed, condensate accumulates in any equipment that cannot be shut down in order to replace the failed trap, and this pooling of condensate impairs the equipment's heating performance.

On the other hand, if the valve remains open, the supply of steam continues uninterrupted and the equipment can continue to be productive. Due to this special design, even if the diaphragm ruptures and becomes technically 'closed' (by remaining in contact with the valve opening due to the flow of steam and condensate), condensate, etc. can still flow through the valve opening via the hole in the center of the valve.

As long as the supply of steam continues, the valve is pushed up and remains fully open.