- Home

- Products

- Steam Traps

- Temperature Control Trap

- Overview

Fluid Control Equipment

Temperature Control Trap

LEX3N-TZ

For correct use

Examples of correct use

Applications designed to utilize the sensible heat of condensate

- Steam tracing, tank heating, etc. for fluids that do not solidify easily at low temperatures (approx. 80°C or lower), such as heavy oil

- Instrumentation tracing for freeze protection, etc.

Examples of incorrect use

Applications requiring the rapid removal of condensate or applications designed to use latent heat of steam

Residual condensate may cause a decrease in heat exchange efficiency and water hammer.

- Steam transport piping

- General steam heating equipment

Tracers with fluid control temperatures above 80°C, applications designed to utilize tank heating or latent heat

Fluid may solidify, causing fluid failure and pipe plugging.

- Steam tracing and tank heating of fluids such as asphalt and molten sulfur that tend to solidify at low temperatures (approx. 80°C or lower).

- Steam tracing, tank heating, etc. for fluids that do not easily solidify at low temperatures (approx. 80°C or lower), such as heavy oil, but are designed to utilize the latent heat of steam.

Overexpansion mechanism

Damage to the bimetal is prevented by the overexpansion mechanism

Temperature control steam traps function through the deflection of bimetals due to rising or falling temperature, allowing the valve to open and close. Due to the possibility of damage to the bimetal following temperature rises when the valve is already on the seat, the LEX3N-TZ employs a coil spring to allow further expansion of the bimetal while the valve is closed: up to 200°C above the set value.

Settable from 50°C to (saturation temperature -10°C)

The temperature control trap can be set from a lower limit of 50°C. However, in order to ensure operation within the range unaffected by outside temperature, the temperature cannot be set so low that there is no difference between the drain temperature and outside air temperature.

The temperature control trap uses a valve mechanism that opens and closes the valve depending on the temperature. Thermostatic traps, including temperature control traps, can detect temperature, but they cannot detect whether it is condensate or steam.

Therefore, if the trap is set to a saturation temperature where the temperature of steam equals the temperature of condensate, steam may continue to flow. This does not mean that the steam trap is fulfilling its role. To prevent this, the valve must be set to open and close at a temperature lower than the saturation temperature, and the upper limit is about 10°C lower than the saturation temperature.

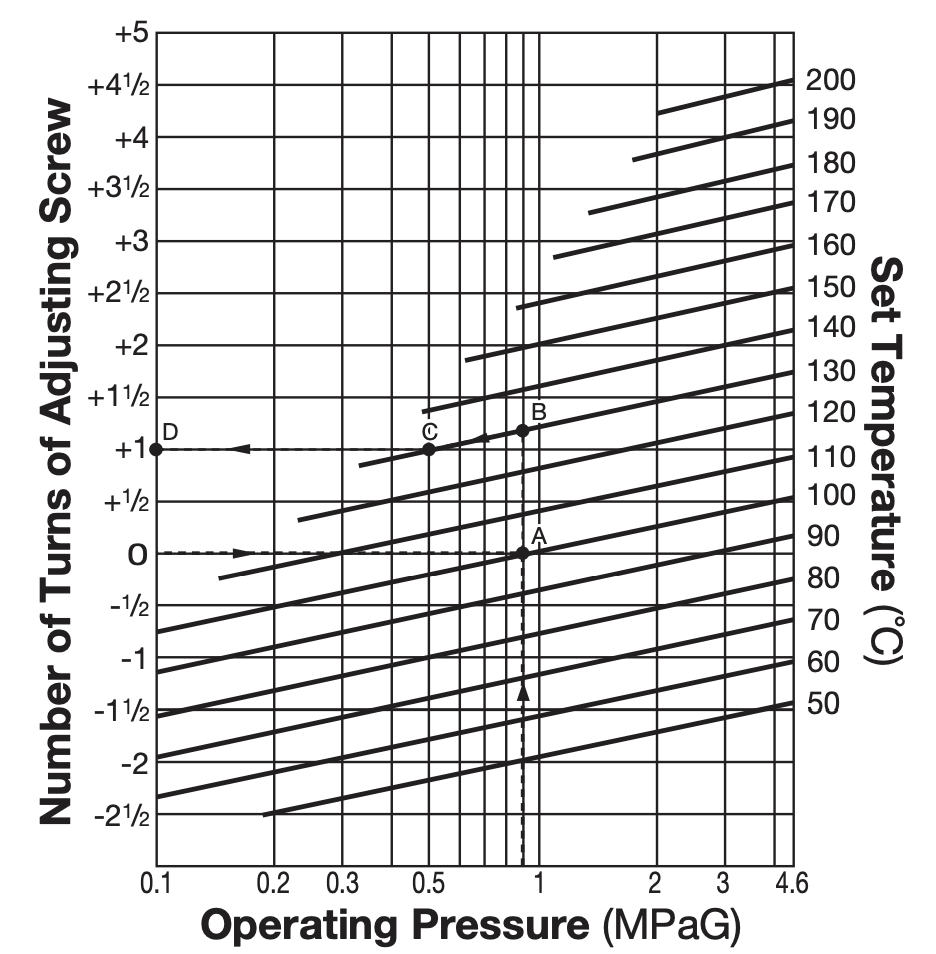

Temperature setting method

The discharge temperature can be adjusted and set to the desired temperature by simply adjusting the screw on the upper part of the LEX3N-TZ with a flat-head screwdriver.

There is no scale or temperature indication on the temperature control trap itself. Therefore, be sure to check the temperature setting diagram for the appropriate model. After determining the steam pressure to be used and the temperature setting, the number of revolutions of the adjusting screw is determined, and the setting is made accordingly.

The condensate temperature set by the above method is very reproducible, and condensate of any temperature can be discharged by setting according to the diagram without using a thermometer.

Cautions for setting operation

Deterioration of the temperature control trap may lead to external steam leakage. Therefore, before performing setting operation, close the front and rear valves of the temperature control trap, and confirm that the trap surface temperature has dropped to room temperature and the pressure inside the trap has dropped to atmospheric pressure.

If external steam leakage is observed, perform maintenance according to the instruction manual, then set the temperature once again. In addition, confirm that there is no external leakage when restarting steam supply. Wear protective equipment like gloves and protective glasses for safety.

Temperature control trap characteristics

The temperature control trap takes about 10 minutes to stabilize at a predetermined temperature after adjustment. Since the temperature of the primary side of the steam trap also changes during this time, it is necessary to watch the temperature fluctuation range of the primary side of the trap to be about plus or minus 10°C.

| Label | Description |

|---|---|

| A | Bimetal |

| B | Valve |

| C | Valve seat |

Note: actual operation is slower

Finally, when adjusting the temperature, make sure that it has stabilized sufficiently before readjusting.