Steam Bulletin

No. 73

Steam Trap Management

Optimizing performance and ensuring system reliability

No matter how durable a steam trap, it will eventually require repair or replacement. Since predicting steam trap failure is extremely difficult, a proactive management program is essential to prevent premature failures, detect malfunctions early, reduce energy waste and CO2 emissions, and maintain consistent production quality.

But how do steam traps fail, and what are the consequences?

Steam trap failure occurs when a trap either leaks live steam or blocks condensate discharge. Condensate blockage can be caused by many factors, and may lead to water hammer, wet steam, and waterlogging in all connected equipment. Live steam leaks can occur due to aging steam traps not subject to regular maintenance, and can represent a significant financial loss.

Read on to learn about key aspects of steam trap management as well as trap testing tips.

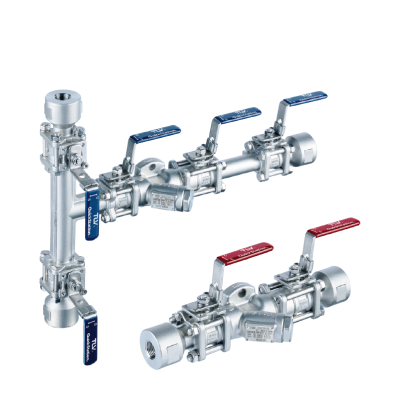

Simplify Steam Trap Maintenance with TLV’s QuickStation®

When ease of trap installation and maintenance is critical, QuickStation® provides a reliable, compact, corrosion-resistant solution. Compatible with various steam trap units for a wide range of applications such as light process use, tracers, and steam mains.

If a plant operates for 8,000 hours a year and the cost of steam is $20 per 1,000 kg [2,204 lb], one failed trap with a small, intermittent leak will cost the plant around $640 annually. A single trap with a constant leak will cost around $2,400 annually.

Product availability and delivery times vary by region.

Contact your local TLV representative for details.

Steam Bulletin is TLV's free monthly email magazine on steam systems, energy efficiency, product selection, and more. We hope you have enjoyed this issue.

If you need assistance with your steam system, TLV can help. Contact our steam specialist staff to apply for a plant survey and/or consultation session.

Finally, make sure to follow TLV on LinkedIn or Facebook for more regular news and updates, and our YouTube channel for video content.

Best regards,

TLV