Fluid Control Equipment

Free Float® Steam Traps for Main Lines

SS Series/FS Series/SH Series

Tight seal with Free Float® and Three-point Seating

Traps for Steam Mains and Tracers

A typical characteristic of steam distribution mains is that the amount of condensate generated in them is usually quite small. Steam traps used for main drainage have long hours of operation and are often installed outdoors. These traps should therefore have the lowest possible functional steam loss to minimize operating cost over the long term and provide long, reliable service.

The TLV SS / SH / FS series have been designed with precisely these points in mind, offering a range of features that make them ideal for use on steam distribution mains.

Free Float

In Free Float® traps, which use no levers or hinges, the float is moved by the buoyant force of the condensate. The distance between the float and the orifice changes in response to the amount of condensate that enters the trap. The float itself acts as the valve head, opening and closing against the seat based on the condensate level in the trap.

Because the Free Float® itself - a precision-ground hollow sphere - is the valve, the entire surface of the float functions as the sealing component. This guarantees superior reliability and long service life. For Free Float® in general, a constant water seal is present to prevent steam loss under normal operation. For applications involving the almost no-load conditions of superheated steam, the 3-point seated Free Float® traps are ideal.

Three-point Seating

The three-point seat provides a precisely machined seating surface and further improves the exceptionally tight sealing. With three-point seating, there is virtually no steam (or air or gas) leakage even in the absence of a water seal.

Less Steam Loss

The combination of the three-point seat and the precision-ground float yields superior sealing properties and long service life. The four-bolt connector provides easy maintenance.

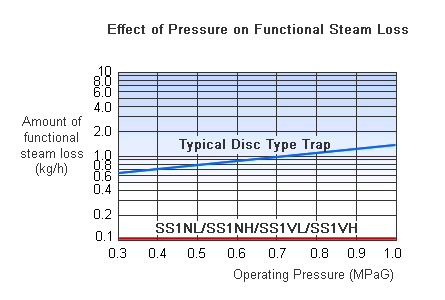

Functional steam loss comparison

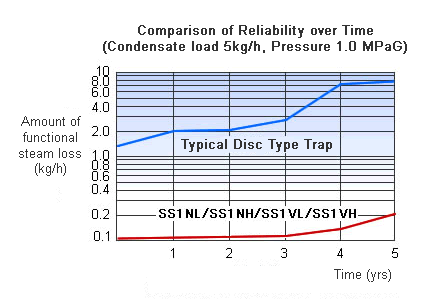

Comparison of reliability over time

Demonstration in the Environmental Technology Verification (ETV) Project by the Ministry of the Environment

SS1N has been tested for its environmental conservation effect in the 2021 Environmental Technology Verification (ETV) Project by the Ministry of the Environment of Japan. (Field: Climate change mitigation technology, energy-saving technology. No. 140-2101)

This project has demonstrated that the SS1N minimizes steam loss associated with condensate discharge, reduces steam consumption, and contributes toCO2 reduction.

Ministry of the Environment website (Environmental Technology Verification Project)

Stainless steel used for the main body

The body and valve seat of the SST series (except SH5VL) are made of stainless steel, which is highly resistant to rust and corrosion, and can maintain the initial high performance for a long time with long service life.

Built-in bimetal automatic blow-off mechanism

Automatic air venting mechanism / Shortened start-up time

Due to low temperatures during initial start-up, the built-in bimetal forces the valve open by lifting the float away from the orifice to automatically vent initial air and low-temperature condensate quickly to shorten start-up time.

(The JH-P series does not have a built-in automatic blow-off mechanism, but it is suitable for steam distribution piping where air is rarely mixed in during long-term continuous operation.)

Air venting capacity (SS1NL/SS1NH/SS1VL/SS1VH)

Compatible with space-saving vertical piping

Models available for either vertical or horizontal piping

Each model in the SS1 / SS3 / SS5 series is available in both a vertical and a horizontal type.

SH5VL is for vertical piping only.

Universal two-bolt connector flange*

The trap can be easily and economically replaced by simply removing 2 bolts. It can be installed on either horizontal or vertical piping.

The SST steam trap series is designed for minimal steam loss at time of condensate discharge, long-term stable performance, and for use on steam distribution mains.

*Applies to models FS3 / FS5 / FS5H