Fluid Control Equipment

Free Float® Steam Traps (Low Pressure)

JX Series/FJ32 Series/SJ Series

Necessary Features of Steam Traps for Process Use

Reduced start-up time by rapid discharge of air

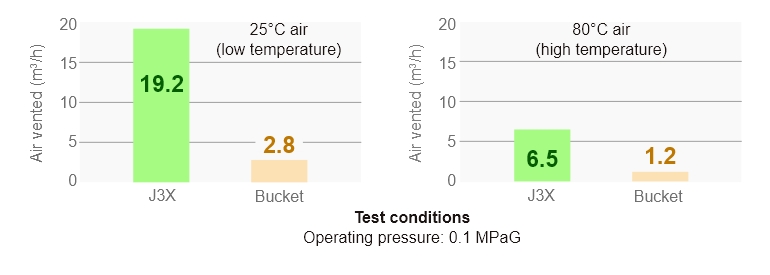

When the X-element is cold, it opens the air vent valve a full 3.5 mm, rapidly discharging initial air 3.7 times more rapidly than the former integral bimetal air vent included in the J3N. Equipment start-up time is also shortened through the rapid discharge of hot air up to approx. 6°C below saturation temperature, something previously not possible.

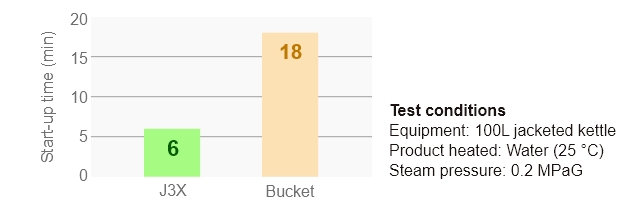

Comparison of Start-up Times

Comparison of Venting Capacities

Improved process heating efficiency

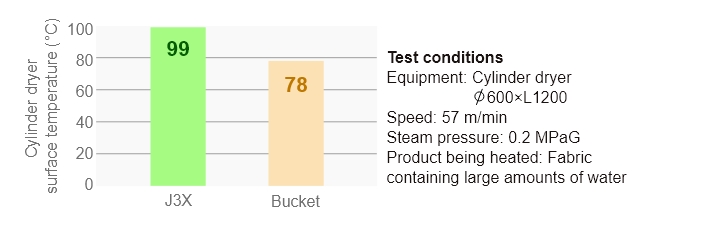

The Free Float® adjusts the valve opening in response to the amount of condensate flow and continuously discharges condensate, preventing any accumulation of condensate inside the equipment. The X-element reacts with great sensitivity to hot air entrained during operation, and discharges it rapidly. These synergistic effects result in maximized heating efficiency.

Comparison of Heating Efficiency

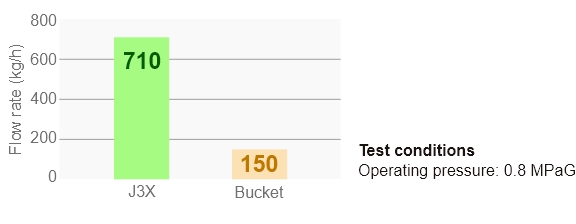

Compact and high capacity

The J3X is roughly the same size as the former J3N, yet it offers a larger discharge capacity than even the former J5N, which was one size larger.

Comparison of Flow Rates

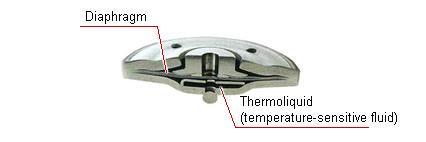

What is an X-element?

The X-element is comprised of a valve and a diaphragm that transmits the force of a thermoliquid (temperature-sensitive fluid). When surrounded by steam, the valve is closed. When condensate, air or other non-condensable gases are present, the valve is open. It can also discharge high temperature non-condensable gases, something bimetal air vents are unable to do. This is made possible due to the special properties of the thermoliquid.

Thermoliquid, like water, is liquid when kept under a certain pressure and temperature, and expands to become a gas when its temperature rises above a certain point. The temperature at which it becomes a gas is approximately 6°C (22°C for air vents) lower than the temperature at which water becomes steam.

So when it is surrounded by steam, the thermoliquid is a gas and the chamber containing the thermoliquid expands and pushes on the diaphragm. This causes the gap between the valve and the valve opening on the diaphragm to close.

In contrast, when the area around the X-element is at a low temperature (when it is either condensate or air), the thermoliquid is in the liquid phase and the valve is not being pushed closed, so condensate and air are discharged from the gap between the valve and the valve opening.

Under Normal Operation

"Fail Open" Safety Feature

Fail safe features are necessary in quality precision instruments. TLV therefore designed the X-element in such a way that the valve remains in the open position ('fail open' safety feature ) in the event the diaphragm ruptures.

If a steam trap fails, the valve may either remain open (blowing) or it may remain closed (blocked). If the valve remains closed, condensate accumulates in any equipment that cannot be shut down in order to replace the failed trap, and this pooling of condensate impairs the equipment's heating performance.

On the other hand, if the valve remains open, the supply of steam continues uninterrupted and the equipment can continue to be productive. Due to this special design, even if the diaphragm ruptures and becomes technically 'closed' (by remaining in contact with the valve opening due to the flow of steam and condensate), condensate, etc. can still flow through the valve opening via the hole in the center of the valve.

As long as the supply of steam continues, the valve is pushed up and remains fully open.

Precision Free Float®: The Best for a Variety of Processes

Continuous condensate discharge

The Free Float® moves up and down in response to the amount of condensate inflow, automatically adjusting the amount of valve opening and continuously discharging condensate. This ensures that no condensate accumulates inside the equipment.

Reduced steam losses

The surface of the liquid inside the trap is maintained above a certain level and condensate is continually discharged through the orifice. Even when there is no condensate flowing into the trap, the precision Free Float® securely seals the orifice closed. This minimizes steam losses during operation.

Ideal for condensate recovery

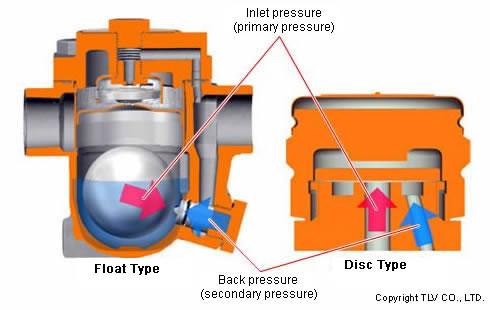

In Free Float® type steam traps, the forces of the inlet pressure and the back pressure act in opposing directions, so Free Float® traps are able to operate normally even under 90% back pressure. This makes them ideally suited for processes with closed condensate recovery systems. In contrast, disc type traps only have a 50% to 80% allowable back pressure because the pressures act in the same direction.

Erosion-resistant design

Constructed to resist erosion through features like: a simple construction with no levers or hinges and only one moving part, the Free Float®; an extra-large surface area in the condensate discharge passage; improved thickness of passage walls from 3 mm to 5 mm (model J3X); and a selection of highly-durable materials.