- Home

- Steam Resources

- Steam Theory

- Waste Steam Recovery

Energy Efficiency

Waste Steam Recovery

Why Waste Steam is Not Recovered

Plant managers often allow steamers, autoclaves, vulcanizers, and other appliances that inject steam directly onto products to vent waste steam to atmosphere. Venting rather than recovering this waste steam is a waste of potential heat energy, but plant managers often choose to do so for one of the following reasons:

- They do not know how to recover this steam.

- They do not want to install a pressurized container that will require regular inspection.

- They believe that the pressure of the waste steam is too low to be reused profitably.

- The boiler is producing more heat than is necessary for the heating process, and there is no other process within the plant where the excess steam can be used.

By collecting and reusing waste steam, such as vented flash steam and excess steam, users can not only put a stop to steam clouds making the plant environment unpleasant but also save energy and lower operation costs.

Common Cases of Steam Wastage

If you have seen any of the following situations at your plant, take note! The steam that is going to waste can be collected and reused.

Condensate in a Collection Tank Evaporates and Flash Steam is Released

Is the condensate in your open-to-atmosphere collection or feed tanks flashing and being lost to atmosphere in the form of steam clouds? Is your tank or recovery pit enshrouded in steam?

- Possible solutions

- Recover low-pressure flash steam, pressurize it, and reuse it: Steam Compressor

- Feed the flash steam into a heat exchanger and use it to heat feed water: Steam Condensing Heat Exchanger

Condensate Loses Heat as it Travels Down Long Recovery Pipes

Is your condensate recovery system ineffective because the condensate loses heat as it travels down recovery pipes?

- Possible solutions:

- Install a flash vessel to flash the condensate and produce low-pressure steam. Then, pressurize that steam before sending it to other processes, or send it to a heat exchanger to heat feed water.

Condensate Flashes When Drained

Have you seen flash steam clouds escaping from your condensate as it is drained away?

- Possible solutions:

- Install a flash vessel to flash the condensate and produce low-pressure steam. Then, pressurize that steam before sending it to other processes, or send it to a heat exchanger to heat feed water.

Effective Use of Waste Steam

The following are three major methods of effectively reusing waste steam.

Collecting, Pressurizing, and Reusing Low-Pressure Steam

Flash steam emitted from condensate that reaches the evaporation point can be collected and reused. When the pressure of flash steam is too low to be reused in processes, it can be mixed with high-pressure steam within a Steam Compressor and pressurized. The 'Steam Compressors' Steam Theory page explains in detail how the Steam Compressor pressurizes flash steam for reuse.

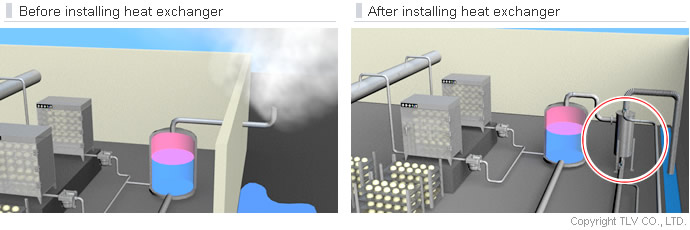

Reusing Flash Steam to Heat Water

Rather than letting flash steam vent to atmosphere, you can send it to a heat exchanger and use it to heat water. The resultant hot water can be used for preheating and washing. As steam exchangers reuse the flash steam indoors, they eliminate the need to install vent ducts and piping, thus reducing installation costs.

Evaporating High-Pressure Condensate and Reusing the Resultant Low-Pressure Flash Steam

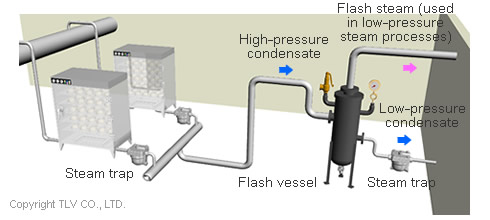

One method of reusing heat from condensate is to "flash" or re-evaporate it, and use the resultant low-pressure flash steam in low-pressure processes. This can be achieved by feeding the condensate into a flash vessel.

As flash vessels have a larger diameter than condensate recovery pipes, the flow rate of the condensate slows as it enters the vessel and the pressure drops, causing a portion of the condensate to flash. This flash steam has a lower specific weight than condensate, so it separates from the liquid and exits through a pipe at the top of the vessel. The remaining low-pressure condensate drains out of a pipe located on the lower half of the vessel.