- Home

- Steam Resources

- Steam Theory

- Bypass Valves

Other Equipment etc.

Bypass Valves

In this tutorial, we are going to take a look at bypass valves.

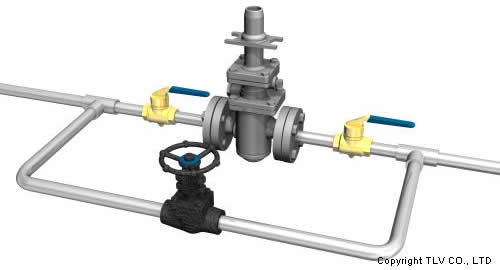

Valves such as pressure reducing valves, control valves and steam traps often have bypass piping installed. The valve in such bypass piping is called a bypass valve.

| Bypass Valve on Steam Trap | Bypass Valve on Pressure Reducing Valve |

|---|---|

|

|

|

What is a Bypass Valve?

The term bypass valve refers to any valve installed in a bypass line, and is not used to indicate a particular valve shape or configuration. So what types of valves are suitable for installation in bypass piping?

The Role of a Bypass Valve

When considering what types of valves are suitable for installation in bypass piping, it is necessary to think about the role of the bypass line. What was the purpose for the installation of that particular bypass line? Bypass piping can roughly be divided into two categories.

- Bypass piping that acts as a backup line to allow operation to continue while damaged equipment such as pressure reducing valves and steam traps are isolated and shutdown during replacement or repair

- Bypass piping whose purpose is to supplement the performance of pressure reducing valves and traps

These different objectives require valves with different features. Therefore, the optimal valve models will be different.

Valves Suitable for Use as Bypass Valves

Example: Back-up Line for Uses Such as Replacement of Equipment

The role of bypass piping for uses such as a backup line during replacement of equipment is not always merely to allow the fluid to continue to flow. There are cases in which it must also act as a replacement for any pressure reducing valves or steam traps involved, so it is important that the bypass line have some 'fluid control' capability. In such cases, globe valves are a suitable type of valve.

Example: Bypass piping to supplement the performance of equipment

Bypass piping installed to supplement performance is designed to handle excessive pressure or flow, so frequently a valve with low resistance is used in the fully open position. Furthermore, if a control valve is included in the installation, the valve needs to have fast opening / closing response. In this type of application, a ball valve is the suitable type of valve.

The subject of valve types is addressed in Types of Valves and Their Applications.

Trap with Built-in Bypass Valve

There is a model of steam trap that has a built-in bypass valve.

To use this trap, at start-up open the bypass valve to rapidly discharge the start-up condensate. Then during normal operation, leave the bypass valve closed so condensate is discharged only through the trap. However, keep in mind that because this bypass valve is built into the trap, it cannot perform the bypass function when the trap is in the process of being replaced. To our knowledge, there are no control valves or pressure reducing valves with built-in bypass features. They must be used in combination with suitable valves.