- Home

- Steam Resources

- Steam Theory

- Removing Condensate from Compressed Air

Compressed Air / Gas

Removing Condensate from Compressed Air

Measures for Dealing with High Humidity

Types of Air Traps

This tutorial is more like "Air Theory" than "Steam Theory."

In some areas, during certain times of year humidity levels can become quite high. Depending on the performance of the air dryer being used with the compressor, in some cases the compressed air can contain large amounts of condensate. Condensate forms inside air when the temperature of the air is cooled to below the dew point. Air traps are used to remove condensate from the air piping. These come in two types - inline types installed directly in the air transport piping, and types installed in branch lines from which the condensate is removed as it flows into the traps. Air traps installed inline are either used in combination with a separator, or a trap with a built-in separator can be selected.

Separators use a cyclone-type mechanism or a baffle plate to forcibly separate the suspended condensate out of the air. There are also dryers that chemically remove condensate from extremities with low flow, such as from air used for instrumentation. With air traps, there is often a large amount of dirt such as rust and scale caused by corrosion present inside the piping, and problems due to clogging of the trap are frequent. At such points in the piping, installation of traps with large orifices and a self-cleaning feature that clears out the valve seat each time the trap operates is recommended. An inline cyclone separator that achieves a high 98% separation efficiency is also recommended for removal of the suspended condensate that is so difficult to remove from the air.

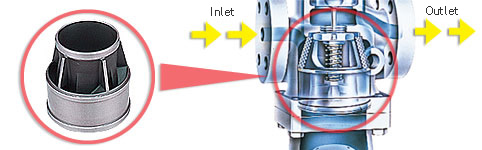

Cyclone Separator

The cyclone separator uses an operation principal in which steam or air is spun at high speeds and the resultant centrifugal force separates out the condensate due to its higher specific gravity.

The condensate droplets are separated out with a separation efficiency of 98% (at a steam or air flow rate of 30 m/s).

The separator is constructed in such a way that after the condensate is separated, it does not get caught up again with the steam or air but instead drops into the trap section and is removed from the system.