- Home

- Steam Resources

- Steam Theory

- Steam Line Energy Saving Tips

Energy Efficiency

Steam Line Energy Saving Tips

Loss of Steam from Steam Lines

Boiler Energy Saving Tips examined ways of saving energy by improving boiler efficiency, but this article will investigate ways of saving energy by reducing heat loss from the pipes that transport the steam created in the boiler.

Steam transport lines are often overlooked when it comes to energy conservation strategies. However, as these lines generally run across long distances within the plant, they have a large surface area and thus a high potential to radiate heat energy or lose steam due to leaks.

There are two major ways in which steam lines can lose heat energy:

- Heat radiation from the surface of pipes and valves

- Steam leakage from valves, pipes, and steam traps

This article will explain how to limit both varieties of heat loss from steam lines.

Preventing Heat Radiation

To limit the amount of heat radiated from steam lines, follow these two steps:

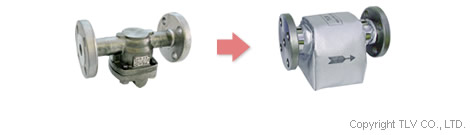

1. Optimize the insulation of existing steam pipes, valves, and fittings

It is important to properly insulate all uninsulated steam pipes; flanges and other fittings; and control valves, PRVs, and other valves. The operation method of a steam trap should first be considered before applying insulation to a steam trap and its associated piping. Thermodynamic and thermostatic traps can remain shut for extended periods of time when insulated and prevent the discharge of condensate from the application to be drained.

The material and thickness of the insulation should conform to local regulations. An economic analysis is recommended to determine the optimum material and thickness for a given pipe size.

|

|

| Properly insulate all traps, valves, and fittings in the plant |

2. Reduce total surface area of piping

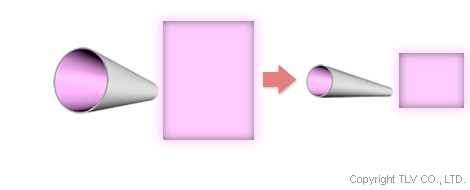

The amount of heat radiated from a pipe is proportional to the surface area of the pipe, so using an over-sized pipe will increase the amount of heat radiated. However, using too small of a pipe size will limit the amount of steam able to be distributed at a given velocity.

A steam distribution line must be sized for the plant’s maximum steam flow rate at an acceptable velocity. This will ensure the pipe is neither too large to waste excessive heat nor too small to limit flow. Pressure loss must also be factored into determining the correct pipe size.

As the surface area of the pipe will also increase with the length of pipe, it is imperative to optimize the piping route to keep radiation losses to a minimum.

|

|

| The loss of heat from piping is proportional to the surface area of the piping |

Preventing Steam Leaks

There are two steps that should be taken to reduce the amount of steam that leaks from steam lines.

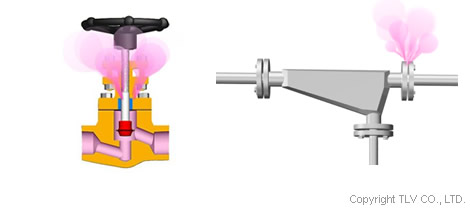

1. Repair leaks from valves and fittings

It is unusual for steam to leak constantly from modern fittings and valve stems, but even small leaks during operation can add up to large losses over time.

These losses can compound financially so it is recommended that leaks are repaired as quickly as possible.

The cost of steam leaks can be calculated using the formula in this article:

|

|

| Steam leakage from valves and flanges |

2. Prevent steam trap leaks

The steam traps installed on steam lines can also be responsible for leaking steam. Steam traps can leak steam for one of the following reasons:

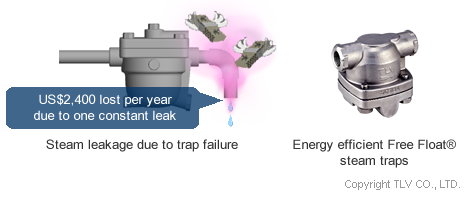

- Leakage due to trap failure

- Leakage due to inherent operation (functional steam loss)

The amount of steam that leaks when traps fail depends on the model of trap and the pressure of the steam, but below is a rough guide to the amount of steam lost from different sized leaks:

- Small, intermittent leak = Approx. 4kg/h [8.8 lb/h]

- Constant leak = 15 kg/h [33 lb/h]

If a plant operates for 8,000 hours in a year and the cost of steam is USD 20 per 1,000 kg [2,204 lb], then one failed trap with a small, intermittent leak in that plant will cost the plant around USD 640 annually. A single trap with a constant leak will cost the plant around USD 2,400 annually.

The amount of functional steam loss from traps during normal operation varies greatly depending on the variety of trap. Conventional steam traps such as disc traps and bucket traps lose 10 times more steam during normal operation compared to energy-efficient Free Float® steam traps.

As conventional trap types leak large volumes of steam over their lifecycle, plants can benefit financially from replacing these traps with TLV Free Float® models immediately rather than waiting until conventional traps fail.