- Home

- Steam Resources

- Steam Theory

- Condensate Recovery: Vented vs. Pressurized Systems

Condensate Recovery

Condensate Recovery: Vented vs. Pressurized Systems

Condensate recovery systems can be classified as either vented-to-atmosphere or pressurized depending on whether condensate is recovered in an open-to-atmosphere tank (vented) or sent to a pressurized vessel/directly to the boiler (pressurized).

Vented vs. Pressurized Condensate Recovery

In a vented condensate recovery system, steam trap inlet pressure or a condensate pump is used to return condensate to an open-to-atmosphere collection tank for use as boiler make-up water, pre-heat or other hot water applications.

In a pressurized condensate recovery system, recovered condensate is maintained above atmospheric pressure throughout the recovery process. The pressurized condensate is generally used as boiler make-up water. Since any associated flash or live steam is pressurized, this steam can be recovered for reuse in applications such as waste heat steam generators (that involve heat exchange) and cascade systems.

Besides pressure, one of the major differences between vented and pressurized systems is the temperature at which condensate can be recovered. In a vented system, because condensate is vented to atmospheric pressure, the maximum recovery temperature of condensate is some value less than 100°C [212°F] due to flashing at that temperature, and subsequent heat loss during from return piping and equipment.

In a pressurized system, condensate can be recovered at much higher temperatures. For example on a closed system with steam at 10 barg [145 psig], condensate can be recovered with a temperature of 184 °C [363 °F] if it is sent to a Deaerator or similar system which captures the higher heat of the higher temperature liquid.

Tip

Vented systems aren't limited to using trap inlet pressure. Pressure can also be equalized if backpressure is too great, in which case condensate drainage equipment such as a mechanical pump/trap assembly is balanced to the condensing equipment itself to constantly equalize with the modulation of the equipment’s pressure. When equalized with equipment, drainage will occur by gravity regardless of whether the equipment steam pressure is positive or in vacuum.

Selecting Between a Vented or Pressurized System

The selection between a vented or pressurized condensate recovery system should be based on a careful economic analysis relative to the gains and losses of each system, which includes the following factors:

- Sensitivity to backpressure

- Amount of equipment being drained and recovered relative to the economic and physical constraints

- Need for a flash recovery system

For a discussion on the differences between using trap inlet pressure and a condensate pump for condensate return, please refer to:

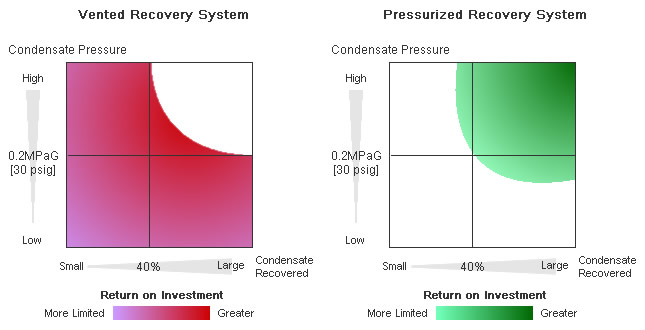

| Typical Range for Vented / Pressurized Systems |

|---|

|

| Since vented recovery systems are typically less costly to design and install, these will typically be used in instances where the return on investment is deemed too low to adopt a pressurized recovery system, for instance, in systems that use lower pressure steam. |

Pros and Cons of Vented Recovery Systems

Because their configuration is much simpler, vented recovery systems typically require a much lower initial investment than pressurized recovery systems. Sizing condensate transport lines is also much easier as piping can be sized like water piping once condensate and flash steam have been separated.

On the other hand, since the collection tank is open-to-atmosphere, a larger amount of energy is lost when condensate flashes to atmosphere – especially in installations where trap inlet pressure is high. The formation of vapor clouds can also have a negative impact on a plant’s work environment.

| Example of Condensate Recovery Vented-to-Atmosphere |

|---|

|

| Condensate recovery systems that are vented to atmosphere often cost less to implement that a pressurized system, but not as much energy can be recovered. |

Pros and Cons of Pressurized Recovery Systems

Pressurized systems involve a much greater number of design considerations than vented systems. For instance, a specialized valve must be installed to regulate the release of flash steam to atmosphere and condensate transport piping must be sized for two-phase flow of steam and condensate.

However, these systems allow for a much greater percent of energy to be recovered compared to vented systems. Additionally, since flash steam is not vented to atmosphere, a greater amount of water can be recovered and reused. The absence of vapor clouds can also considerably improve a plant’s work environment.

| Example of Pressurized Condensate Recovery |

|---|

|

| Condensate recovery systems that are pressurized often cost more to implement that a system vented to atmosphere, but also greater energy savings. |

Summary Table

| Vented Recovery | Pressurized Recovery | |

|---|---|---|

| Recovered Condensate Temperature | Up to 100 ºC [212 °F] | Up to 180 ºC [356 °F]* |

| System Configuration | Simple | Advanced |

| Initial Costs | Lower | Higher |

| Running Costs | Varies | Varies |

| Piping Corrosion | Significant (condensate comes into contact with air) | Slight (no contact with air) |

| Vapor Clouds | Large amount (if condensate temp. is high) | Minimal amount |

| Recovery Applications | Boiler make-up water Pre-heat Water for cleaning, etc. | Mainly for direct feed to boiler, and Flash Steam Recovery Applications |

*May be higher. Limited by max operating temperature of pump and peripheral equipment.