- Home

- Products

- Check Valves

- Check Valves

- Applications

Fluid Control Equipment

Check Valves

CK Series

Case Study: Incorporating into equipment for simple, compact configuration

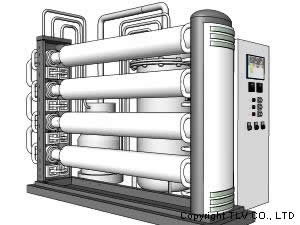

Water purification system, SIP processes

| Equipment used |

|

|---|

Problem

In addition to water piping, water purification equipment requires piping for steam used for sterilization, which is complex to handle and requires space. The site would like to maintain the equipment/plant size, even if a steam sterilization process is added to the equipment.

Water purification system, SIP processes

Water purification system, SIP processes

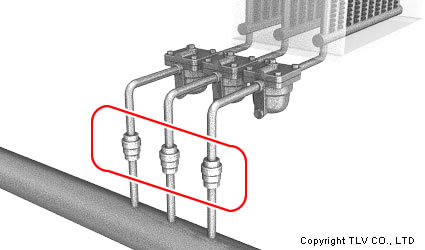

Solutions

- Utilization of check valves with high sealing performance, compact size, and flexible vertical and horizontal installation.

- This allows the piping to be designed compactly, and the size of the equipment and plant can be maintained.

Key improvements

- CK3 is made of stainless steel and suitable for pure water applications

- CK3 has excellent sealing performance and can eliminate the need for a manual valve for disconnection.

- CK3 is compact and can be installed horizontally or vertically, allowing for greater flexibility in piping routing

Applications

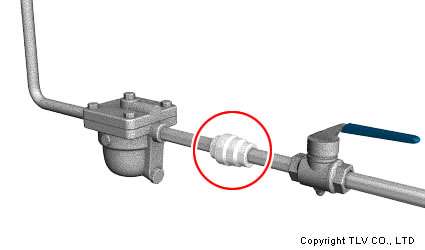

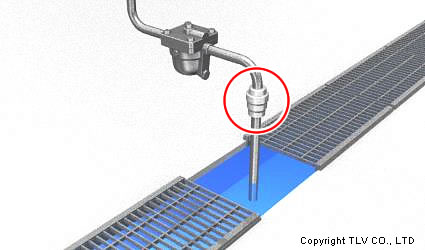

Prevention of backflow from steam trap outlet

| Condensate collection piping | Steam trap outlets |

|---|---|

|

|

| Prevention of condensate backflow into non-operational equipment | Prevention of backflow |

| Before vertical rises | Before pits |

|

|

| Prevention of return flow water hammer | Prevention of condensate suction after shut-down |

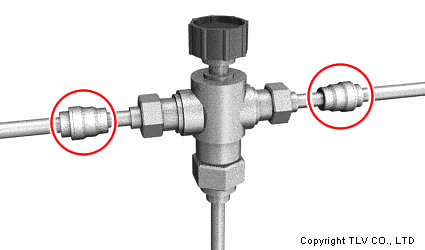

Prevention of fluid backflow

| Mixing valve |

|---|

|

| Prevention of cross-mixing of steam and feed water lines |

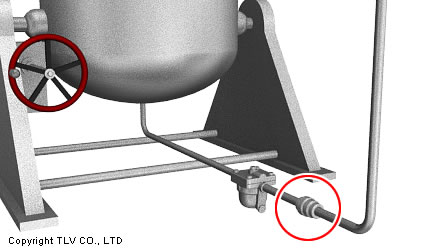

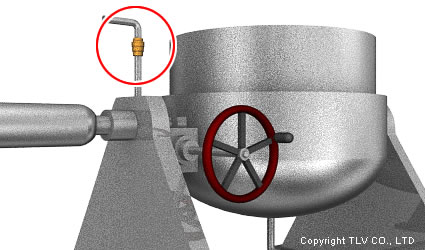

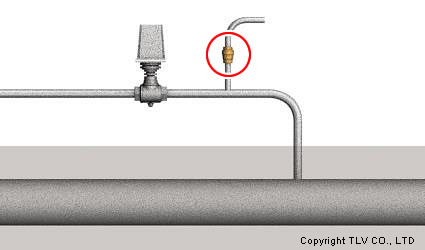

Vacuum breaking function for equipment and piping

| Reactor kettle | Wastewater lines |

|---|---|

|

|

| Vacuum breaking function for equipment and piping prone to condensate discharge problems due to vacuum formation | |