- Home

- Steam Resources

- Steam Theory

- Steam System Accessories Part 1

Steam Trap Considerations

Steam System Accessories Part 1

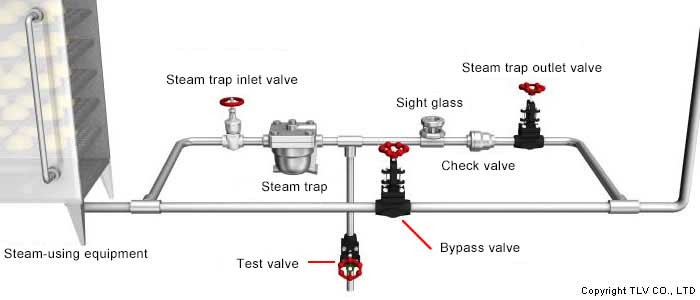

Accessories around the steam trap

For effective use of steam traps, the following equipment should also be installed to ensure correct operation of the trap, to check its operation when necessary, and to facilitate maintenance.

- Accessories required for operation

Check valves and automatic non-freeze valves - Accessories required to check operation

Sight glasses and test valves - Accessories required for maintenance

Inlet valves, outlet valves, bypass valves, and strainers

This article covers the first two types of equipment: accessories required for operation, and to check operation.

Accessories required for operation

Check valves

Since traps do not have a built-in way to prevent condensate backflow, TLV recommends to install a check valve at the trap outlet when several trap outlets are aggregated for condensate collection, or when there are vertical rises after the trap outlet.

For more information on check valves, refer to Check Valve Installation and Benefits.

Automatic non-freeze valves

In colder climates regions, residual condensate in the steam trap or inlet piping can freeze when the trap is inactive, causing damage to steam-using equipment or the steam trap itself in some cases. To prevent this, install an automatic non-freeze valve on the trap.

The non-freeze valve is a simple combination of a spring and a valve, which opens when the trap internal pressure drops below a certain amount, typically at shut down, and closes above a certain pressure, usually at start-up. When the non-freeze valve opens, the residual condensate drains by gravity, so the valve should be installed at the lowest point of the equipment.

However, in extremely cold climates the valve itself may freeze when condensate is discharged, therefore the freeze prevention function cannot be fully guaranteed. Consult with TLV if you are unsure of the suitability before installation.

Accessories required to check operation

Sight glasses

Installing a sight glass at the steam trap outlet is a good way to visually check the operation of the trap. This is not necessary if the trap discharges to atmosphere and the piping outlet is close to the trap outlet, but if the trap discharges to a collector pipe, a sight glass can be installed to check the trap operation at a glance.

Test valves

When the steam trap outlet connects to condensate recovery piping, a test valve may be installed to visually check the actual condensate discharge from the trap and the presence of steam leakage, in addition to checking by sight glass.

When using a test valve, the steam trap outlet valve is closed and the test valve is opened to check the condition of the discharged condensate. However, test valves should only be used when the condensate can be safely discharged to a drainage pit.

In "Steam System Accessories Part 2", we explain the equipment required for maintenance.