蒸気のことならテイエルブイ

- North America

- Latin America

- Europe

- Middle East

- Asia

- Oceania

- Other Regions

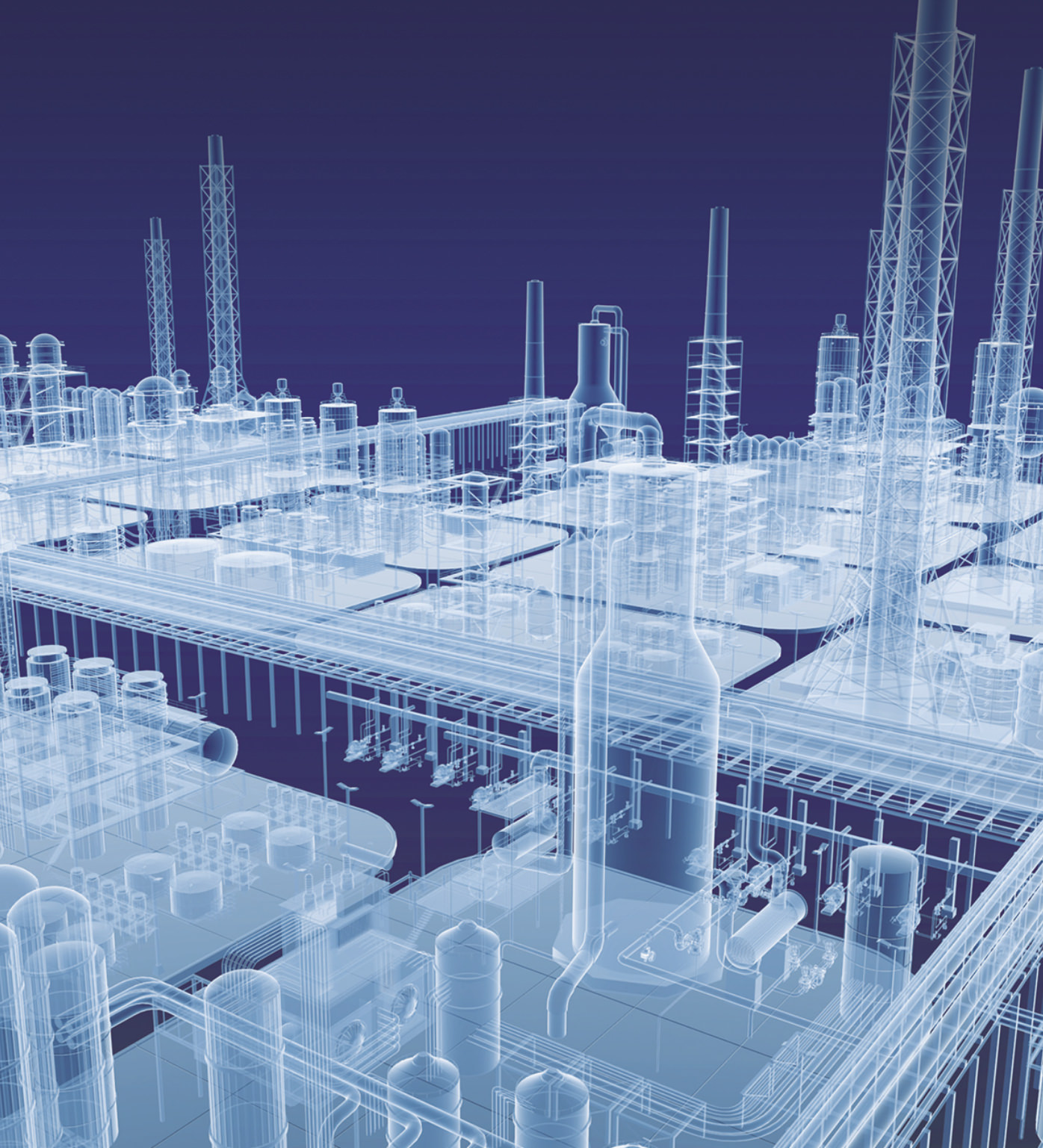

Peace of mind

for your plant

“Trouble Less Valve” – This is what the name TLV stands for.

TLV was founded in 1950 with the goal of creating the world’s No. 1 steam trap.

Witnessing the problems and challenges faced by plants, our pursuit evolved into a determination

to bring plants peace of mind.

This inspired a change – what customers need are solutions, not just products.

Drawing on our experience, TLV will continue to provide solutions and value to plants,

striving to become the world’s No. 1 steam specialist.

We support

your steam system

Making steam

work for you

Improved productivity,

energy conservation,

and safe and reliable operation

Overcoming challenges

in your industry

TLV Group

Subsidiaries in 13 countries, and a network of over

100 distributors in more than 50 countries

100 distributors in more than 50 countries

Supporting steam-using industries across the world

Key Industries

Incomparable Originality

A tradition of innovation

Product development starts from our customer’s perspective.

Our goal is to produce products that exceed your expectations.

To meet the needs of the market, we have developed a broad range of solutions including steam traps, valves and separators, as well as sophisticated system products and software.

To date, we have obtained over 4,900 patents and utility models across the world, underlining our commitment to creating new, innovative technologies.

A3NSteam-heated,

A3NSteam-heated,

condensate-cooled

disc-type steam trapOur first milestoneWe developed the A3 after seven years of dedicated research. Designed to alleviate the high frequency of steam trap failure, it was over ten times more durable than existing products. Despite being three times more expensive than competitors, it earned an outstanding reputation in the market. Its legacy is inherited by the improved A3N, a bestseller even today. Free Float®Meeting energy-saving needsThe Free Float® is a symbol of TLV’s technical expertise. Our steam traps incorporating this technology have very low steam loss and long service life. Today, our Free Float® technology is used widely in a broad range of products.

Free Float®Meeting energy-saving needsThe Free Float® is a symbol of TLV’s technical expertise. Our steam traps incorporating this technology have very low steam loss and long service life. Today, our Free Float® technology is used widely in a broad range of products. VACUUMIZER®Vacuum steam heating systemExpanding the possibilities of steamWe have also pioneered the development of system solutions – devices that incorporate multiple TLV products to perform specialized, controllable functions. Our vacuum steam-heating system VACUUMIZER®, for example, allows you to harness steam’s heating properties even below 100 °C.

VACUUMIZER®Vacuum steam heating systemExpanding the possibilities of steamWe have also pioneered the development of system solutions – devices that incorporate multiple TLV products to perform specialized, controllable functions. Our vacuum steam-heating system VACUUMIZER®, for example, allows you to harness steam’s heating properties even below 100 °C.

Products that exceed

your expectations

your expectations

Quality First

Manufacturer at heart

TLV is first and foremost a manufacturer.

Each product we manufacture is proof of our unwavering dedication to quality, and is vital to our solutions.

We pursue the highest quality and consistently produce products that play important roles in our customers' plants.

We are constantly refining production processes to ensure that we deliver high quality products on time to our customers around the world.

Factory certifications

Certification by the International Organization for

Standardization (ISO9001/14001)

High-Pressure Gas Production Facility Inspector Certification

EU Directives (CE Marking, PED, ATEX) Certification

General Construction Business License (Plumbing Business/Machinery, Equipment and Facility Business, Japan)

Conformity inspections compliant with the Japanese Consumer Product Safety Act

“TLV Quality” production systemOur manufacturing quality is supported by constant development and honing of production processes and technology, an environmental and quality assurance system that maintains reliability and dedicated people at all stages of our operations.

“TLV Quality” production systemOur manufacturing quality is supported by constant development and honing of production processes and technology, an environmental and quality assurance system that maintains reliability and dedicated people at all stages of our operations. Integrated production managementWe promptly issue shipping and assembly instructions for every order placed, and design custom production processes to ensure that your products are delivered on schedule. The TLV members in charge of each process, from receiving orders to manufacturing to shipment, work closely to handle even sudden order amendments.

Integrated production managementWe promptly issue shipping and assembly instructions for every order placed, and design custom production processes to ensure that your products are delivered on schedule. The TLV members in charge of each process, from receiving orders to manufacturing to shipment, work closely to handle even sudden order amendments. Quality-orientated manufacturingOur “quality first” policy is at the heart of everything we do. Our production staff work closely with R&D, striving to develop both products and manufacturing processes of outstanding quality that enable long-lasting productivity benefits.

Quality-orientated manufacturingOur “quality first” policy is at the heart of everything we do. Our production staff work closely with R&D, striving to develop both products and manufacturing processes of outstanding quality that enable long-lasting productivity benefits.

Manufacturing “TLV Quality”

Customers First

Providing the best possible solutions

Through developing products and studying the steam-using processes in our customers’ plants, we came to realize that there are many problems in the steam system that cannot be solved by just providing products.

To proactively contribute to safe and reliable plant operations, we created the CES (Consulting・Engineering・Services) philosophy and team.

The aim of CES is to offer the best possible solutions to problems that steam-using plants face, increasing energy efficiency, protecting the environment, and improving product quality and productivity.

Delivering tailored solutions to steam system problems

Consulting·Engineering·Services

ConsultingThe first step towards devising solutions is to thoroughly and accurately survey the plant. We work closely with you to identify the root causes of problems and propose effective, realistic solutions.

ConsultingThe first step towards devising solutions is to thoroughly and accurately survey the plant. We work closely with you to identify the root causes of problems and propose effective, realistic solutions. EngineeringNext, our engineers put these solutions into practice. Making the most of our extensive experience in a wide range of industries, we provide optimal designs for your plant’s steam system and applications.

EngineeringNext, our engineers put these solutions into practice. Making the most of our extensive experience in a wide range of industries, we provide optimal designs for your plant’s steam system and applications. ServicesTLV’s highest priority is making sure that your problems are solved.

ServicesTLV’s highest priority is making sure that your problems are solved.

We not only check the effectiveness of each solution once it is introduced but also provide follow-up support to deal with unexpected issues, aiming to complete recovery work within 24 hours.

Comprehensive support from

CES specialists

CES specialists

Optimize your steam system asset®

The organizational benefits of utilizing steam to its full potential and treating the steam system as an asset are significant.

SSOP® (Steam System Optimization Program) improves the safety and reliability of your plant.

In SSOP® we create clear visualizations of even complex steam systems and implement mechanisms that help keep plants in their optimal state and deliver sustained value to the organization through improved plant operation and maintenance.

Continuously optimizing steam systems through visualization

Steam System Optimization Program

Condition MonitoringWe use diagnostic devices to monitor and visualize the entire steam system in real time. Visualization and analysis of the operating condition of all steam-using equipment reveals opportunities for further improvement.

Condition MonitoringWe use diagnostic devices to monitor and visualize the entire steam system in real time. Visualization and analysis of the operating condition of all steam-using equipment reveals opportunities for further improvement. Timely OptimizationWe establish a system that detects early signs of failure, enabling fast and accurate maintenance to be performed before trouble occurs. This supports safe and reliable plant operation, reduces risk and saves energy.

Timely OptimizationWe establish a system that detects early signs of failure, enabling fast and accurate maintenance to be performed before trouble occurs. This supports safe and reliable plant operation, reduces risk and saves energy.

Steam is an asset

Creating the future of steam plants

There is more to SSOP® than total plant surveys and state-of-the-art monitoring systems.

We also uncover risks early and take preventative measures, mitigating the negative impact of system failure.

By uncovering risks early and taking preventative measures, we aim to prevent the negative impact of appliance or system failure.

A wide range of steam facilities around the world are reaping the rewards of SSOP® for their critical tracing applications, turbines, reboilers and other assets.

- STEP 1Real-time monitoringCreate visualizations of the entire steam system and demonstrate the current state of the plant.

- STEP 2Trend managementAnalyze data from sensors to determine each application’s likelihood of failure.

- STEP 3Predictive maintenanceCarry out predictive repairs, helping workers focus on plant operation.

Bringing peace of mind to your plant

Consulting·Engineering·Services

Consulting·Engineering·Services

Steam System Optimization Program

Steam System Optimization Program