- Home

- Products

- Steam Traps

- Free Float® Steam Traps for Main Lines

Fluid Control Equipment

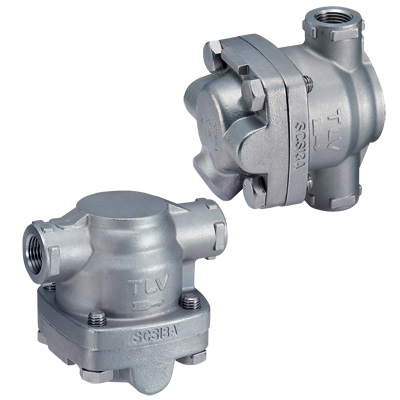

Free Float® Steam Traps for Main Lines

SS Series/FS Series/SH Series

Free Float® steam traps for main lines that provide a tight seal even under low condensate load conditions

A typical characteristic of steam distribution mains is that the amount of condensate generated in them is usually quite small. Steam traps used for main drainage have long hours of operation and are often installed outdoors. These traps should therefore have the lowest possible functional steam loss to minimize operating cost over the long term and provide long, reliable service.

The TLV SS / SH / FS series have been designed with precisely these points in mind, offering a range of features that make them ideal for use on steam distribution mains.

Free Float® Steam Trap Series Pamphlet

QuickTrap® Series Pamphlet

Free Float® and Other Float Steam Trap Discharge Capacities Pamphlet

Benefits and Features

Energy Conservation

The valve opening is under a continuous water-seal, so no steam can escape through the valve. In the case of small condensate loads, such as in superheated steam lines, the Free Float’s 3-point seating holds the float tightly against the valve opening to ensure that no steam is allowed to escape.

Prevention of Start-up Trouble

The automatic air vent design opens the air vent valve at start-up to discharge any low temperature air inside the system. This prevents air-binding, which can be caused by initial air.

Long Service Life

The spherical Free Float® rotates during operation, allowing any point on its surface to act as the valve seal and thus ensuring long service life.

Application Areas

- Steam main lines, steam headers, tracers, etc.

Product Details

| Model | Photo | Connection | Installation Orientation | Body Material | PMO (psig) | TMO (°F) | Discharge Capacity (lb/h) | ||

|---|---|---|---|---|---|---|---|---|---|

| SS1 |  | Screwed | Horizontal and Vertical Models | Cast Stainless (ASTM A351 Gr.CF8) | 300 | 428/752 | 475 | Specifications | Manual |

| SS3N / SS3V |  | Screwed | Horizontal and Vertical Models | Stainless (ASTM A240 Type 316L) | 300 | 752 | 475 | Specifications | Manual |

| Socket welded | |||||||||

| SS5N / SS5V |  | Screwed | Horizontal and Vertical Models | Stainless (ASTM A240 Type 316L) | 450 | 800 | 1510 | Specifications | Manual |

| Socket welded | |||||||||

| SS5NH / SS5VH |  | Screwed | Horizontal and Vertical Models | Stainless (ASTM A240 Type 316L) | 650 | 800 | 530 | ||

| Socket welded | |||||||||

| FS3 QuickTrap® |  | Screwed Socket welded Flanged | Both Horizontal and Vertical | Stainless (ASTM A240 Type 316L) | 300 | 752 | 475 | Specifications | Manual |

| FS5 QuickTrap® | Both Horizontal and Vertical | Stainless (ASTM A240 Type 316L) | 450 | 752 | 1510 | ||||

| FS5H QuickTrap® |  | Screwed | Both Horizontal and Vertical | Stainless (ASTM A240 Type 316L) | 650 | 800 | 530 | Specifications | Manual |

| Socket welded | |||||||||

| Flanged | |||||||||

| SH5VL |  | Socket welded | Vertical pipelines | Cast Steel (ASTM A216 Gr.WCB) | 925 | 800 | 700 | Specifications | Manual |

| SH5NL |  | Socket Welded or Flanged | Horizontal | Cast Steel (ASTM A216 Gr. WCB) | 925 | 800 | 770 | Specifications | Manual |

| SH5NH |  | 1,150 | 500 | ||||||

| SH6NL |  | Socket Welded or Flanged | Horizontal | Cast Steel (ASTM A216 Gr. WCB) | 925 | 800 | 2110 | Specifications | Manual |

| SH6NH | 1,500 | 860 |

- PMO = Maximum Operating Pressure

- TMO = Maximum Operating Temperature

The latest version of each product's instruction manual can be found on this page.