- Home

- Steam Resources

- Steam Theory

- Double Trapping

Steam Trap Problems

Double Trapping

One problem related to condensate drainage sometimes encountered in factories is the installation of one trap and a second trap in series further down the line. This issue is known as 'Double Trapping'.

Double Trapping is usually done as a temporary measure, where a “master trap” is installed on a condensate line with a multitude of traps failing further upstream. In some cases, it may be that a second trap is installed immediately downstream of another trap as a kind of back-up to the first trap. Neither of these installation ideas are recommended.

While installing two traps in series might appear to be a good safety measure, this practice is not recommended because it can lead to trap blockage and waterlogging of all equipment trying to drain into it, similar to when a trap is completely blocked.

Double Trapping Does More Harm Than Good

Setting two traps in series might appear to be useful as:

- A back-up in case the first trap fails, or as a way to quickly stop steam leaks before blowing out a vent

- A way to reduce vapor clouds

However, a simple look at the operating mechanism of steam traps can explain why setting two traps in series is never recommended.

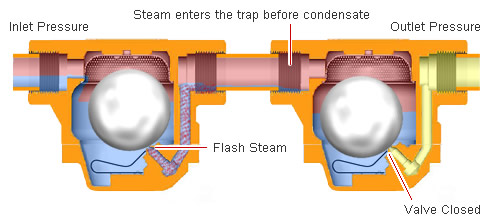

| Steam Locking Issue Caused by Double Trapping |

|---|

|

| Steam produced through the leakage of live steam or the flash evaporation of condensate may cause the valve in the second trap to close. |

Why Double Trapping Doesn't Work

Reason #1: Intended to Stop Flow of Live or Flash Steam

If a trap has failed, it will leak live steam. If it functions properly, then a portion of the discharged condensate will flash into steam because of the pressure differential. Either way, when two traps are set in series, live or flash steam exits the first trap with multiple effects:

- Backpressure on the system increases (due to the restriction of the second trap and piping diameter for the steam encountered)

- The second trap is closed by the presence of steam (steam locking), thus interrupting flow

- Waterlogging and water hammer are two subsequent negative effects

For more information related to these issues, please read:

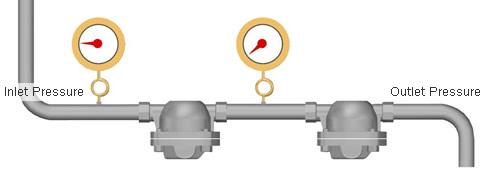

Reason #2: Pressure Differential and Trap Size

A single trap would have the sizing benefit of using the full pressure differential between inlet and outlet when selected. When double trapping is used, the pressure differential has to be divided between two traps. The result is that a small single trap would need to be replaced by two traps larger than the single one.

Even so, as mentioned above, the second trap will close on live or flash steam, so continuous flow is impeded and causes waterlogging. Additionally, in cases of higher backpressure in the return line, one of the traps may need to be substantially larger to adjust for the smaller differential pressure across it to avoid a “stall” condition.

For further details on Stall, please read:

| Pressure Differential Issue |

|---|

|

| Because available pressure differential is divided by 2 traps, if it is not great enough for flow to overcome the outlet pressure, condensate will pool at the inlet of the first trap, which is why both the first and second trap would need to be over-sized. |

Even if both traps are oversized, another reason to avoid double trapping is the likelihood that problems arise from differences in the timing of the operating cycles of both traps.

Resolving Problems Related to Condensate Discharge

In short, whether from steam locking or the lack of discharge synchronization on the second trap, double-trapping leads to water hammer or other serious problems and should be avoided.

As a basic principal, if trap failure is a concern, in addition to having spare traps on hand, a block valve should always be installed at the inlet and outlet side of steam traps to allow for quick and easily replacement. Often, a bypass valve to drain may also be installed. Also, if it necessary to have a back-up for a critical process, then one solution is to install a trap in parallel to be ready in case of switching over. If vapor clouds from condensate discharge are a concern, setting up a flash steam vessel to collect and possibly reuse flash steam will help reduce visible steam clouds in addition to helping improve efficiency of the system.