The World’s First Service for Quantifying and Mitigating Risk to Steam Systems

Optimize your Steam System Asset®

Steam system optimization programs focus on conserving energy and improving system reliability. Such programs have typically provided estimates of the energy savings that plants can achieve. However, they have not been able to quantify the savings that plants can achieve by improving the reliability of their steam systems.

Since 2015, in collaboration with industry leading asset integrity specialists, TLV has been developing a way to quantify these savings by measuring the probability and cost of equipment failure.

Utilizing our steam engineering know-how and extensive experience with inspecting and optimizing steam traps and related steam equipment, we created SSRM, the world’s first service for quantifying and mitigating risk to steam systems.

Interested in using SSRM to assess the risk to your plant?

Contact us today to find out how!

Goals

- Identifying and quantifying risk factors and reliability issues

- Reducing risk and mitigating potential threats

- Evaluating risk mitigation actions

- Achieving energy savings

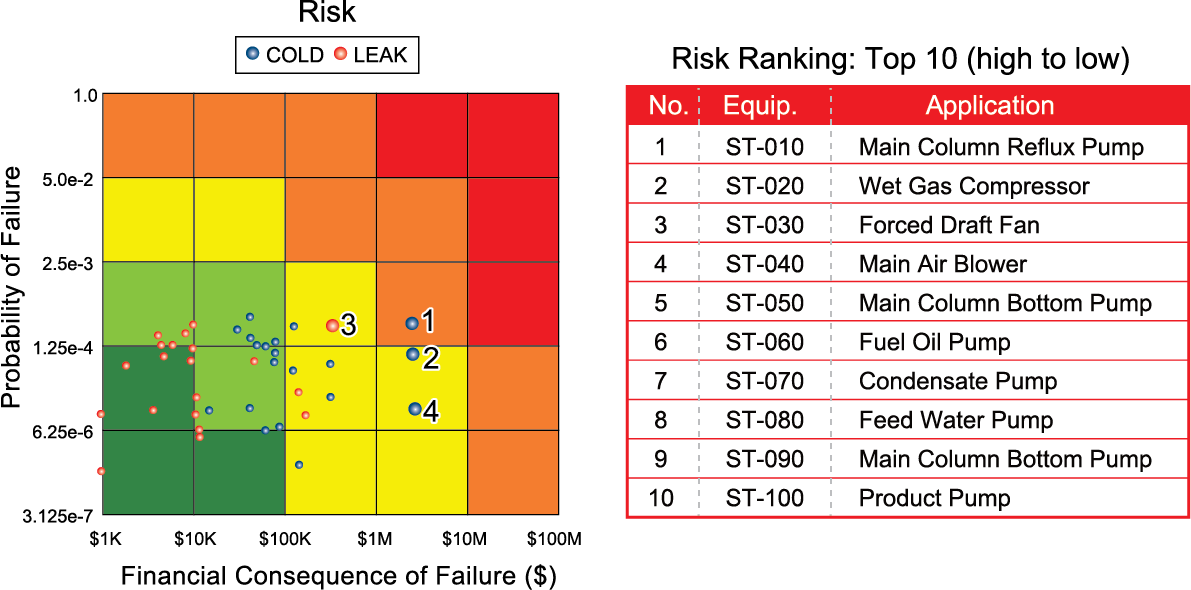

Probability of Failure Before and After Risk Mitigation Action

(Plotted on an SSRM Matrix)

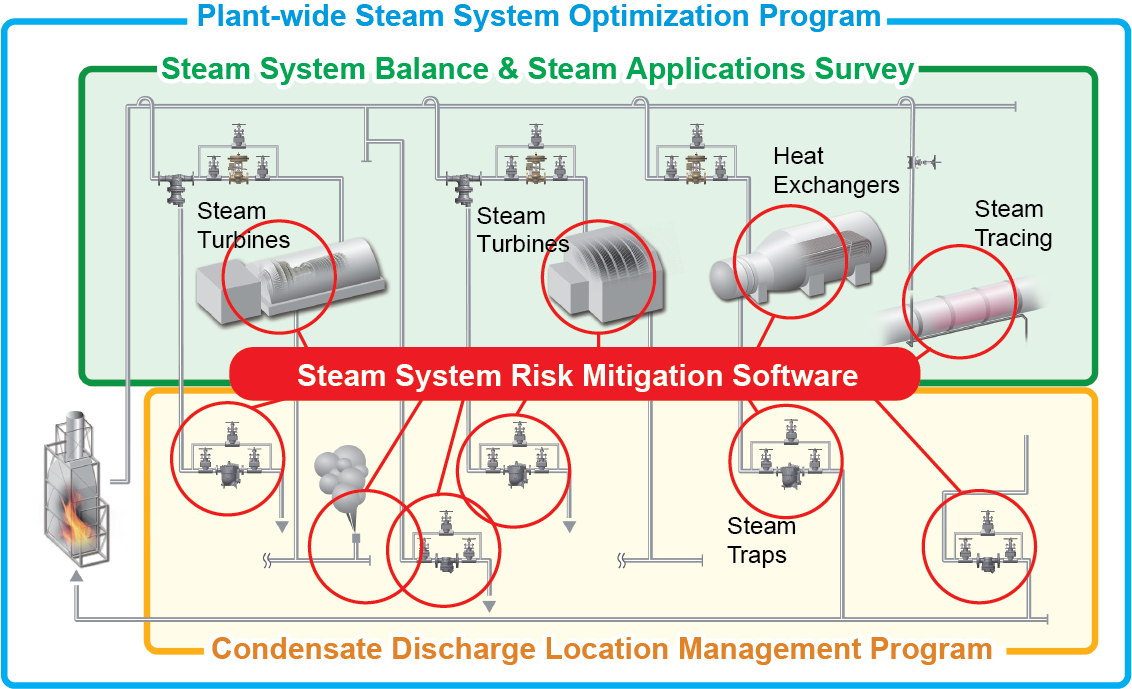

Scope

SSRM focuses on measuring risk to:

- Steam applications, such as

- Steam turbines

- Heat exchangers

- Critical steam tracing systems

- Gas flares

- Steam stripping

- Related condensate discharge locations

- Steam distribution and condensate recovery piping

Scope of SSRM

Target

Failure of a steam distribution line at a refinery and petrochemical complex due to water hammer

SSRM aims to mitigate and reduce the probability of all threats to steam applications and related condensate discharge locations, including:

- Steam turbine trips

- Heating problems

- Water hammer

- Stall

- Steam leaks

SSRM helps mitigate risk to refinery’s steam turbines |  |

| 1 | Potential risk uncovered and quantified |

At the fluid catalytic cracking (FCC) process unit of a refinery, TLV performed a survey of all steam turbines and and assessed their current risk using SSRM methodology. The assessment results provided a quantitative basis for prioritizing maintenance resources, while highlighting the current high-risk equipment. As one example, TLV discovered that the steam supply to the turbine driving the main column reflux pump had a significantly high moisture level, its steam traps were inadequate for their service, and the turbine governor had eroded in the past due to the presence of unwanted condensate. These factors contributed to a high probability of failure assessment for this turbine. As it was a critical element of the process unit, the cost of failure for the turbine was also assessed to be high, giving it the highest overall risk score on the SSRM matrix. Refinery steam turbines ranked by risk on SSRM matrix |

| 2 | Mitigation of turbine risk |

Based on the results of the field survey and SSRM analysis, TLV devised and implemented solutions to mitigate potential risks. Our solutions ensured a dry steam supply to the turbine in question, and prevented condensate backup in the turbine as well as associated piping. Finally, we evaluated the effect of these mitigation actions using SSRM and formulated a cost-benefit analysis based on the results. |

Interested in using SSRM to assess the risk to your plant?

Contact us today to find out how!