- Home

- Products

- Condensate Recovery

- PowerTrap® (Mechanical Pump)

- Applications

Fluid Control Equipment

PowerTrap® (Mechanical Pump)

GP Series

The Mechanical Pump (PowerTrap) GP Series addresses concerns such as:

- No power source in remote or restricted areas (e.g. explosion proof)

- Difficulty integrating pumps into complex electrical systems

- Insufficient differential pressure between the equipment and condensate return

A mechanical pump provides a solution whilst avoiding these issues by utilizing readily available steam or compressed air.

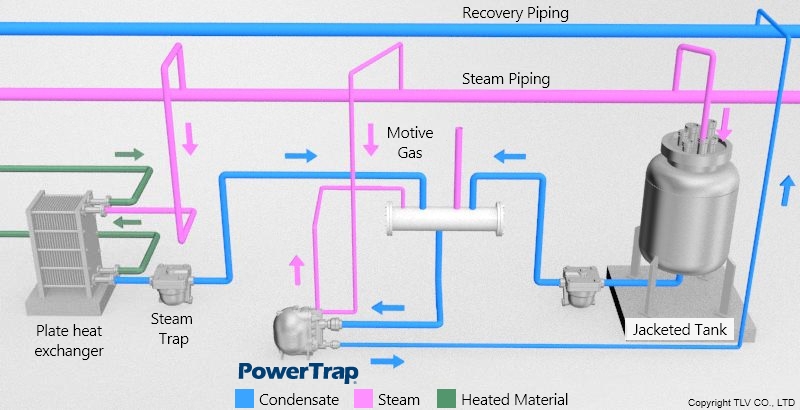

Plate heat exchanger: Beverages

A common layout in food factories is that the steam traps are installed on the floor and the condensate recovery pipes are near the ceiling. The pressure of steam used in the production of food is relatively low which can result in an insufficient differential pressure for effective condensate discharge and recovery. Equipment is widely dispersed for various uses, such as product firing, extraction and CIP. By using PowerTrap, it is possible to collect and recover the condensate discharged by using motive steam/air, preventing build-up.

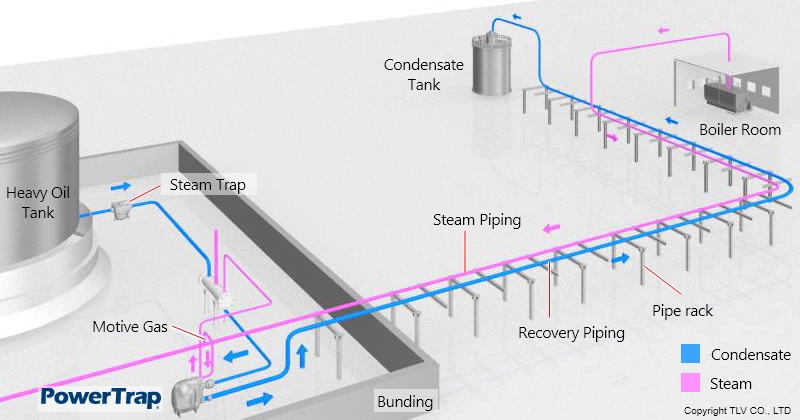

Tank Heater: Heavy Oil Fired Power Plant

Condensate generated from the tank heater lacks the pressure to overcome the bunding and thus cannot be transported to a far away condensate tank. Therefore, a pump is needed. These applications typically have no power supply meaning that electrical pumps cannot be used. The PowerTrap, however, does not use electricity and can pump the condensate using steam or air, allowing for condensate recovery from locations without a power source. Additionally, by collecting the condensate discharged from the tank heater it is possible to avoid the issues that arise from discharging the condensate to the ground.

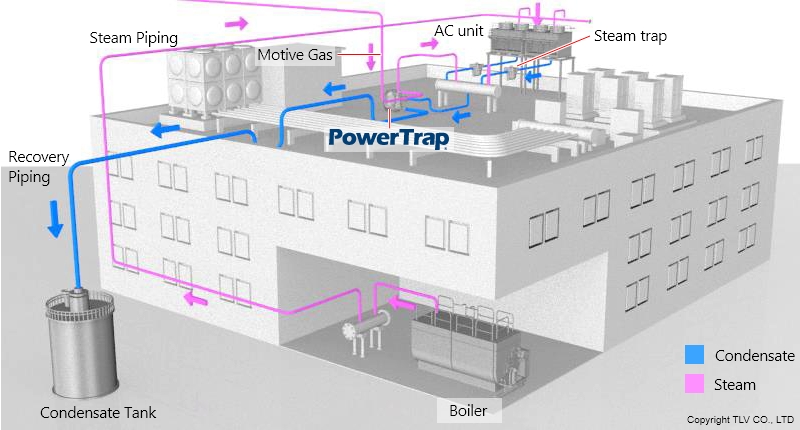

Air conditioner (rooftop installation): beverages

When collecting condensate from equipment installed on the rooftop to a condensate tank located downstairs, the overall process utilizes gravity for collection. However, at the rooftop level, there is various equipment and piping obstructing the condensate line, resulting in numerous rises in the recovery piping. This causes an increased back pressure on the equipment, making condensate recovery difficult. However, by using the PowerTrap, even with low steam pressure, the condensate can be pumped over the rises in the recovery piping to the condensate tank downstairs using steam or air pressure.

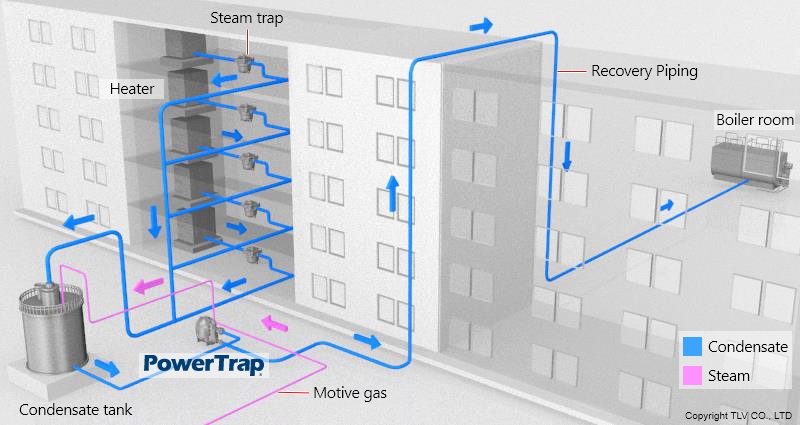

Various heaters: feed, food, fiber

Condensate generated on each floor of a five-story factory is initially collected in a condensate tank. Ideally, it would be collected back to the boiler room for reuse, but the boiler room is located on the opposite side of the building, making the long-distance piping required for collection a major hindrance. However, by using the PowerTrap, it becomes possible to pump the condensate over the large distance to the boiler room.