Fluid Control Equipment

PowerTrap® (Mechanical Pump with Built-in Trap)

GT Series

What is the stall phenomenon?

Air heaters often get damaged. Water hammer sounds can be heard from inside the equipment. Uniform heating is not possible... If you are experiencing any of these phenomena in your equipment, it may be the "stall" phenomenon.

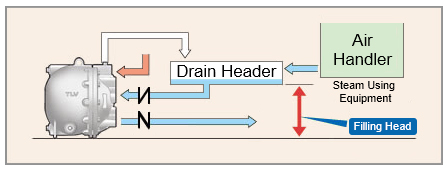

When the steam pressure inside a heat exchanged becomes lower than the outlet pressure (back pressure), condensate accumulates inside the equipment without being discharged from the trap, causing damage or breakage of the equipment due to water hammer, pitting due to corrosion, and uneven heating.

GT Series Benefits

Built-in steam trap

The GT Series has a built-in steam trap function, which discharges condensate as a steam trap when the internal pressure of the equipment is higher than the back pressure, and pumps condensate as a mechanical pump when the internal pressure is lower.

The hybrid system automatically switches between the two functions, eliminating the need to select a steam trap, which requires specialized knowledge.

Snap-action mechanism with no gas leakage

The unique snap-action mechanism instantly switches between air supply and exhaust. Therefore, there is no operating gas leakage, which is common with crank mechanism type, preventing erosion of the valve and valve seat.

The main internal parts are made of stainless steel, and the compression coil spring is made of highly durable nickel base alloy.

Easy Maintenance

- No need to detach from piping to perform maintenance.

- Fast and easy cleaning of intake valve, which is prone to scale build up, by simply opening a plug to remove (GT10).

- The snap-action unit can be replaced as a whole unit, reducing work time.

Low filling head

Each model of Power Trap enables a low filling head, enabling its use in equipment with low drain outlets.

| Model | Min. Filling Head |

|---|---|

| GT10 | 30 in |

| GT14M | 14 in |

| GT14L | 12 in |

| GT10L |

The inlet pressure required on the primary side for the pump to operate (indicated by height) is called the "minimum filling head." A pump with a low filling head is ideal for use with equipment that typically have low condensate outlets, such as air heaters.

Stainless steel check valves for durability

- Newly-developed high-capacity CK3MG and CKF3MG check valves (CKF3MG for flanged GT10).

- Improved durability, quiet operation and reduced return hammer after condensate discharge.

- Center-guided for maximum reliability, even with dirty condensate.

Option

Thermal insulation cover (for outdoor use): Prevents heat dissipation and improves maintenance work efficiency.

In addition to preventing burns, the special heat-insulating cover made of glass mat and glass cloth can be attached and removed with "Velcro" fasteners, contributing to shorter working hours.

"Velcro" is a registered trademark of Kuraray Co.

| Model name | RK12 | RK11 | RK10 | RK9 |

|---|---|---|---|---|

| Appearance |  |

|||

| Compatible PowerTrap model |

GT14M | GT14L | GT10 | GT10L |

Other Optional Products

Various optional products are available to make effective use of the PowerTrap.

| Name | Stainless steel body |

Liquid level gauge* (*) | Pressure gauge | Strainer on condensate inlet side |

|---|---|---|---|---|

| Appearance |  |

|

|

|

| Compatible PowerTrap model |

GT14M/GT14LGT10/GT10L | GT14M/GT14L/GT10/GT10L | Contact TLV | |