- Home

- Steam Resources

- Steam Theory

- Problems With Temperature Control

Steam Control

Problems With Temperature Control

Temperature Control in Everyday Life

Many offices, schools, and homes use air conditioners to maintain a comfortable environment in hot summers and cold winters. To save energy and protect the environment, many companies and governments encourage setting air conditioners at a high temperature (e.g. 28°C [84°F]) when cooling, and at a low temperature (e.g. 20°C [68°F]) when heating. The air conditioner is an example of a common household appliance that we use to control temperature. Other common appliances that control temperature include baths, ovens, and stoves.

In this article, we will examine temperature control in the context of steam heating applications. Steam is commonly used as a heat source in industrial applications. Some typical examples of temperature control using steam include:

- Steam heating to create hot air

- Steam heating to produce hot water

In such applications, the pressure of the steam is adjusted so that the hot air or hot water reaches the required temperature. It may seem that controlling the temperature of the product is the best way to heat products to the desired temperature, but actually this is not always the case.

The Difficulty of Measuring Temperature

To control the temperature of a product, one needs to be able to accurately measure the temperature of that product. However, this can be a surprisingly difficult task. Different temperatures might be measured depending on where the sensor is located, or there could be a time lag in the measurement.

Another problem is the difficulty of measuring products as they are being manufactured. For example, on lines where sheets of material are continuously moving, it can be difficult to contact the material directly to measure its temperature. Accurate temperature measurement is the first step toward accurate temperature control. If temperature is not measured accurately, it is difficult to control it effectively.

But even if you can measure a product’s temperature accurately, you may still have problems controlling its temperature if the thermometer takes time to reach the same temperature as the product. For example, if the amount of supply steam is increased, the temperature of the product may rise gradually rather than immediately. This is especially true when there is a large amount of product to be heated. In such a case, you need to be able to measure the change in temperature quickly and accurately to control the product’s temperature effectively.

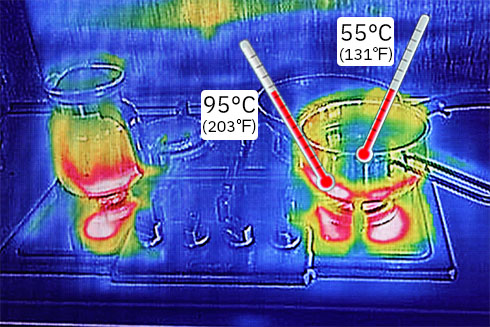

For example, consider when cooking with a pot on a gas stove. The areas where the flame is touching will be the hottest while other areas may undercook the food. If we were to measure the temperature of the pot with a kitchen thermometer, it would show a higher temperature at the center above the flame compared to the other areas of the pot.

Also, when cooking, you can use the residual heat after turning off the stove for the finishing touches. However, controlling the temperature is difficult as there tends to be a delay after changing the setting.

Alternatives to Temperature Control

Problems with temperature control occur regardless of the heat source, but they can be avoided and controlled when steam is used as a heat source. This is done by controlling the pressure of the supply steam rather than the temperature of the product. Controlling steam pressure is not always possible, but there are many processes in which it is done effectively.

In Steam Pressure Control, we will examine in detail how heating temperature can be controlled by changing the pressure of saturated steam.