- Home

- Products

- Air and Drain Traps

- Air Traps for High Viscosity Condensate

Fluid Control Equipment

Air Traps for High Viscosity Condensate

TATSU2

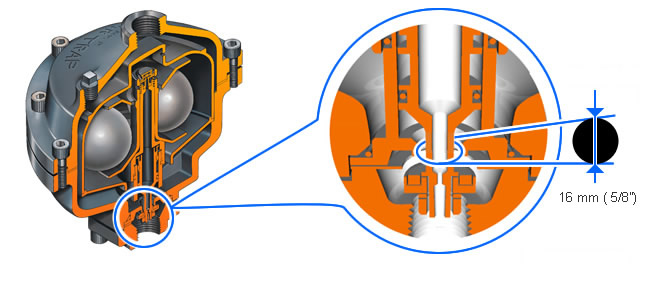

Air traps for high viscosity condensate, with large valve seat and self-cleaning function.

Discharge condensate mixed with high-viscosity fluids such as oil from compressed air distribution piping using TLV's TATSU2 air trap for high viscosity fluids.

Hydraulic oil can get mixed in with condensate during transport through compressed air piping. This often clogs air traps, impeding discharge.

The TATSU2 was purpose-built with a large 16 mm (5/8") diameter valve orifice and a special self-cleaning function to automatically discharge condensate and oil. This unique design helps prevent damage to the equipment and the products being manufactured.

Benefits and Features

Stable operation of air-using facilities

Discharges large quantities of condensate

Large size orifice smoothly discharges any entrained oil, rust and scale together with the condensate. Self-cleaning of the trap interior during each condensate discharge keeps the orifice free of any obstructing build-up.

Innovative design

- A large 16 mm (5/8") diameter orifice for easy discharge of oil, rust and scale

- A large condensate discharge capacity, reaching up to 7.4 t/h (16,280 lb/h)

- Automatic self-cleaning function during operation keeps the valve seat free of any blockage

Application Areas

- Air piping containing oil, rust or scale

- Air-using receiver tanks or other equipment with higher viscosity condensate.

Product Details

| Model | Photo | Connection | Body Material | PMO (psig) | Maximum Differential Pressure (MPa) | TMO (℃) | Max Condensate Load (kg/h) | Specifications | Manual |

|---|---|---|---|---|---|---|---|---|---|

| TATSU2 |  |

Screwed | Cast Iron (FC250) |

1.0 | 0.2 | 80 | 7400 | Specifications | Manual |

- PMO = Maximum Operating Pressure

- TMO = Maximum Operating Temperature

- The latest version of each product's instruction manual can be found on this page.