- Home

- Steam Resources

- Steam Theory

- Boiler Energy Saving Tips

Energy Efficiency

Boiler Energy Saving Tips

Important Points to Consider When Aiming to Reduce Boiler Energy Use

When attempting to reduce the steam energy used in one's plant, two of the first points that should be checked are 1) the potential operational efficiency of the boiler, and 2) the actual efficiency at which it is being operated.

The potential operational efficiency of a boiler is determined by its technological capabilities, so it is important to install a highly efficient boiler to begin with. However, even if a highly efficient boiler is installed, it will not lead to energy savings if it is not operating in an energy efficient manner. Methods of improving the boiler's actual operational efficiency include, for example:

- using multiple small capacity boilers rather than one large capacity boiler, and adjusting the number of boilers running at the same time depending on the load;

- fine-tuning boiler operation time based on the volume of steam required by plant processes.

How Efficient is the Boiler at Your Plant?

First, let's examine how efficient the boiler is at your plant. Start by checking the design efficiency rating of your boiler. This is usually published in product catalogues and/or safety data sheets. Keep in mind, however, that this rating describes the efficiency of the boiler when operating under ideal conditions, and may not be an accurate reflection of the efficiency at which the boiler is operating at your plant. The efficiency rating of your boiler should be taken as an ideal level, and plants should work to make their boiler's operational efficiency as close to this rating as possible.

The operational efficiency of a boiler is an expression of the percentage of heat energy generated from the heat energy input. It can be found using the following formula:

| Boiler efficiency (%) = | Heat output (1) | ×100 |

| Heat input (2) |

(1) Heat output [kJ] = Mass of steam produced [kg] x (Specific enthalpy of steam - Specific enthalpy of feed water) [kJ/kg]

(2) Heat input [kJ] = Quantity of fuel used [kg] x Net calorific value of fuel [kJ/kg]

This can be rewritten in more detail as:

| Boiler efficiency (%) = | msteam × (H - h) | ×100 |

| mfuel × NCV |

msteam = Mass of steam produced [kg]

H = Specific enthalpy of steam [kJ/kg]

h = Specific enthalpy of feedwater [kJ/kg]

mfuel = Quantity of fuel used [kg]

NCV = Net calorific value of fuel [kJ/kg]

”Mass of steam produced” refers to the net mass of steam produced by the boiler. This can be found by measuring steam mass flow at the outlet of the boiler, or by subtracting the mass of boiler blowdown from the mass of feed water. As the actual mass of steam generated varies based on the amount of steam required by the plant at a given time, it is important to measure the amount of steam used each hour, being sure to measure at times when the steam load is heaviest as well as times when it is lightest. These measurements will allow you to calculate and evaluate the hourly boiler efficiency rate.

When compared to average daily boiler efficiency rates, hourly efficiency rates can shed light on the effect that change in load has on boiler efficiency. If there are large fluctuations in the efficiency of the boiler at certain times in the day, plant managers should consider strategies for alleviating those fluctuations, such as making changes to production timing and processes. In the same way, plant workers should also compare variations in steam flow rate in summer and winter months with average annual flow rate, and make changes to alleviate fluctuations where possible.

Boiler Energy Saving Tips

To ensure that the boiler is operating efficiently, TLV recommends that you do the following:

- Set a standard maximum percentage of excess combustion air.

- Set suitable minimum levels of fuel quality and viscosity to improve the efficiency of fuel combustion.

- Regularly measure and record fuel usage, exhaust gas temperature and residual oxygen content, boiler pressure, steam output, and boiler blowdown water levels.

- Set standards regarding combustion settings, boiler maintenance and inspection, and regularly inspect and maintain the boiler. Keep records of all inspections.

- Regularly examine feedwater quality and ensure that it conforms to local industry standards.

A high percentage of excess combustion air will lead to a high volume of exhaust gas. TLV recommends that users manage boilers to keep excess combustion air percentage around 10-30% (110-130% of the required stoichiometric air). Further, if boiler feedwater quality is poor, blowdown water and carryover levels can increase, leading to a drop in boiler efficiency. Local feedwater quality regulations typically specify maximum levels of various elements, so refer to these when carrying out inspections.

There are also cases where other applications connected to the boiler are responsible for energy losses. For example, certain large boilers are equipped with a deaerator that sprays steam onto boiler feedwater. Often, deaerators spray more steam onto feedwater than is needed, resulting in energy losses.

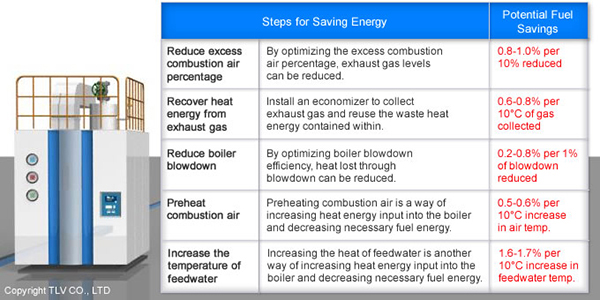

The list below summarizes the steps that plants can take to improve the efficiency of their boiler, and the energy savings that can be expected from carrying out these steps. Note that these are figures represent potential savings in a standard plant, and actual savings will differ depending on the variety, capacity, and fuel source of the boiler.

Increasing the temperature of feedwater and optimizing the excess combustion air percentage, in particular, can lead to large energy savings. The boiler is the source of all steam in the plant and is the chief consumer of fuel, so ensuring that it runs in an energy efficient manner is of utmost importance.

Need help assessing the efficiency of your boiler? The steam specialists at TLV can help. Contact us today: