- Home

- Success Stories

- Process automation reduces start-up times and product defects for rubber product manufacturer

Process automation reduces start-up times and product defects for rubber product manufacturer

Product defects and required man hours reduced by implementing an automatic control system for temperature and pressure inside the autoclave

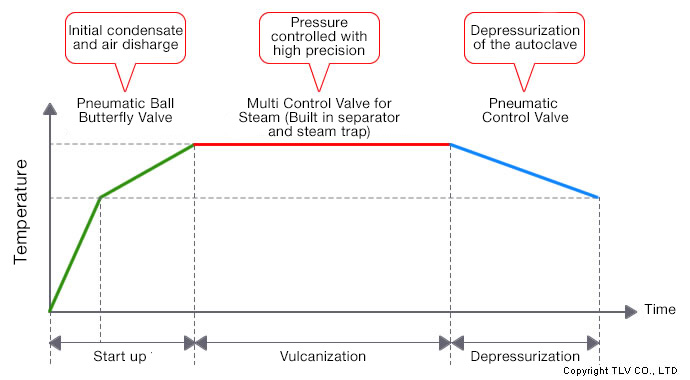

The operation of a vulcanizing autoclave is typically a batch process which involves placing product inside the large pressure vessel, filling the vessel with steam, and once vulcanization is complete, venting and depressurizing in order to remove the product. The ability to eliminate air from inside the vessel during the initial stages of steam supply to the autoclave greatly affects the process time and quality of the product.

A rubber product manufacturing company was having difficulty removing air at startup. As a result, the process had to be continually monitored, requiring the time and the attention of skilled operators to man the autoclave. By introducing an automatic control system that regulates both temperature and pressure, the company successfully reduced product defects and man-hours, and was able to standardize operations.

Rubber Product Manufacturing Company

| Application: | Vulcanizing Autoclave |

|---|---|

| Business Operations: | Processed rubber goods |

Products Used:

Problem

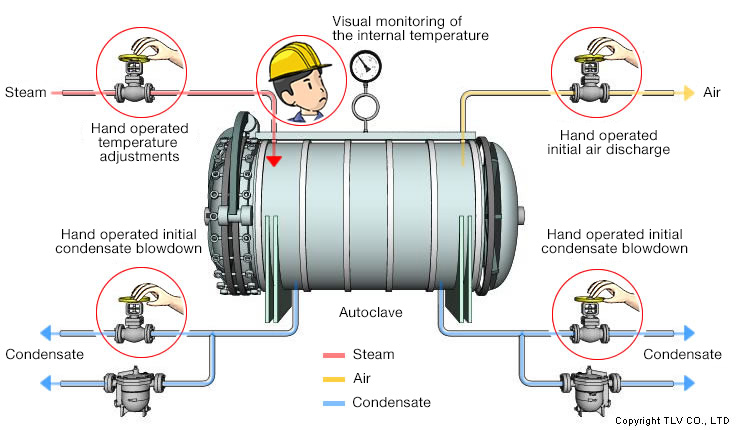

Difficulty in initial air removal through manual valve operation often led to poor quality products

Air was removed at startup via the operation of manual valves such as the exhaust valve and the steam trap bypass valves installed on the vulcanizing autoclave. It was impossible to completely eliminate the air, leading to insufficient temperature rise within the autoclave and prolonged heating times. The manual valves required minor adjustments each batch and as a result, operators were troubled by product defects like color blurring, pockmarks, and quality discrepancies between batches.

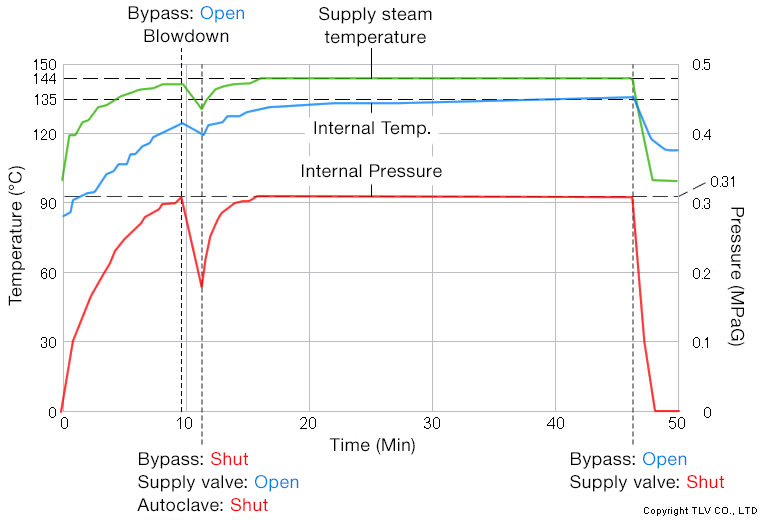

Measurements in the vulcanizing autoclave before improvement

Due to Dalton's law of partial pressure, residual air in the autoclave hinders the internal temperature from rising, preventing it from reaching the supply steam temperature and leading to product defects.

Reason for Inquiry

The company attended a seminar hosted by TLV and encountered a case study exactly like their problem

At the TLV Steam Academy Seminar, the issue they were facing was discussed in one of the sessions. After consulting with the speaker, they organized a site inspection and a meeting with TLV engineers who created an improvement proposal.

Solution

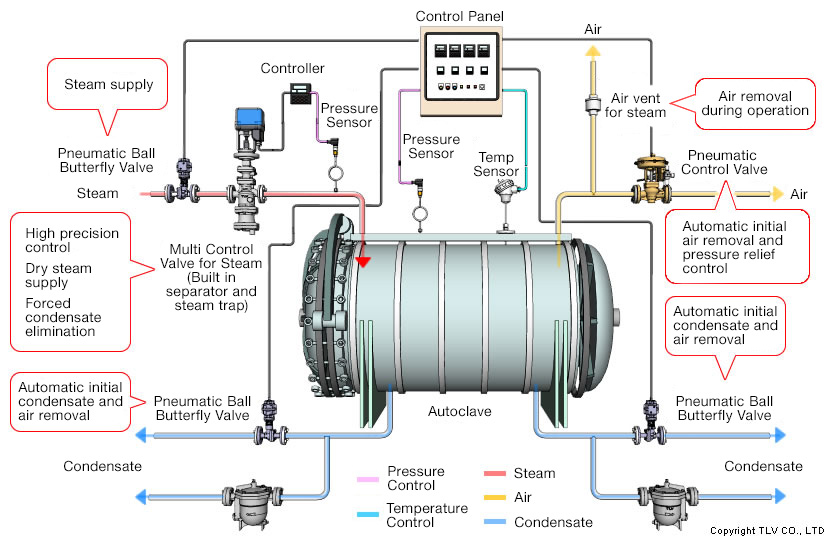

An automatic control system incorporating control valves for the steam supply and exhaust to monitor and optimize the internal temperature and pressure

In addition to the exhaust control valve, an automatic valve on the steam trap bypass line aids in rapidly discharging air at startup. An air vent, which utilizes TLV's balanced pressure thermostatic capsule, discharges any residual air from the autoclave chamber before or during operation. A high-precision multi-control valve for steam maintains a stable pressure within the autoclave, even when air is expelled during operation. This control valve also includes an integrated steam trap and separator with a 98% condensate separation efficiency. In addition to supplying stable pressure, it supplies dry steam, reducing startup time and preventing quality issues caused by entrained condensate.

Results

Achieved reduced startup time, improved product quality, and cut operator work time

By quickly and efficiently venting air from multiple locations, not only was the startup time significantly reduced, but the operators were able to bring the autoclave's internal temperature close to the supplied steam temperature. As residual air was discharged, the temperature during vulcanization stabilized, and the number of product defects was reduced.

The gradual depressurization of the autoclave after the vulcanization process was also automated, eliminating manual valve operation which heavily relied on experience and intuition. The process has been transformed into a standardized and documented procedure, enabling individuals of various experience levels to confidently carry out the tasks at hand.